Lanulfi Steel

Expertise, accuracy.

The perfect mix

Between art and science.

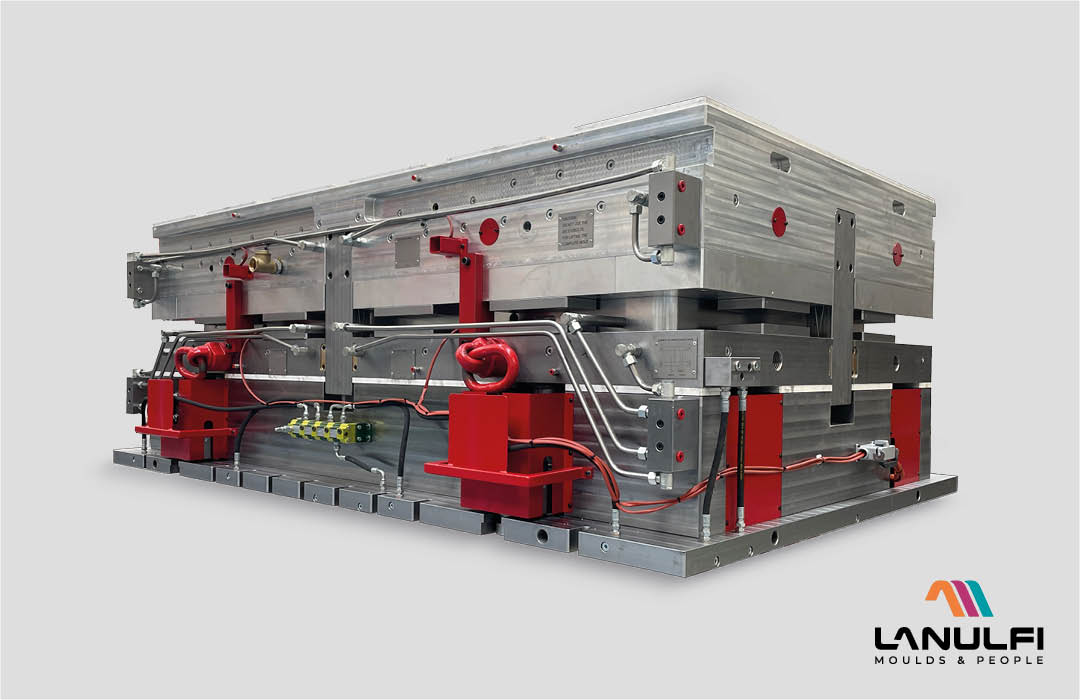

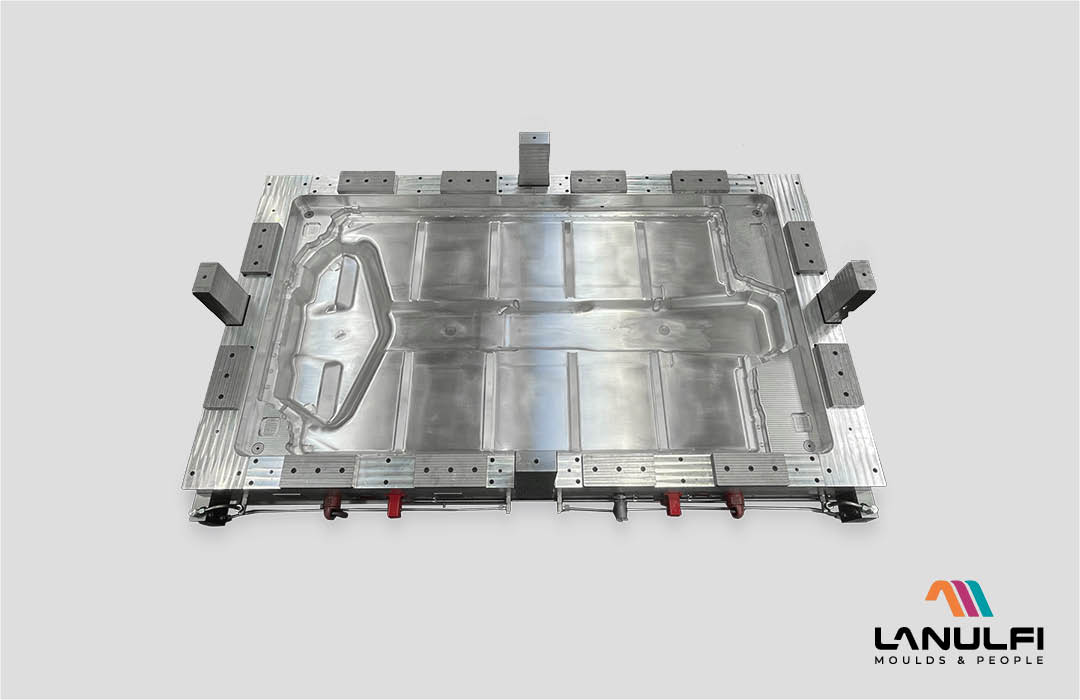

Making a steel mold requires craftsmanship skills and high-precision machinery. Steel is processed with the help of various techniques, such as milling, turning, EDM and grinding to extremely tight tolerances. The finishing stage is of paramount importance, as it determines the surface quality of the mold and, consequently, the appearance and performance of the finished product. Throughout the entire production chain, Lanulfi guarantees very high quality standards and a keen problem-solving attitude.

Thermosetting moulds

Lanulfi's long experience in machining has enabled it to establish itself among the leading companies in moulds for resins and composite materials.

We produce molds made from steel blocks for the following technologies: SMC - GMT

TYPES AND SECTORS

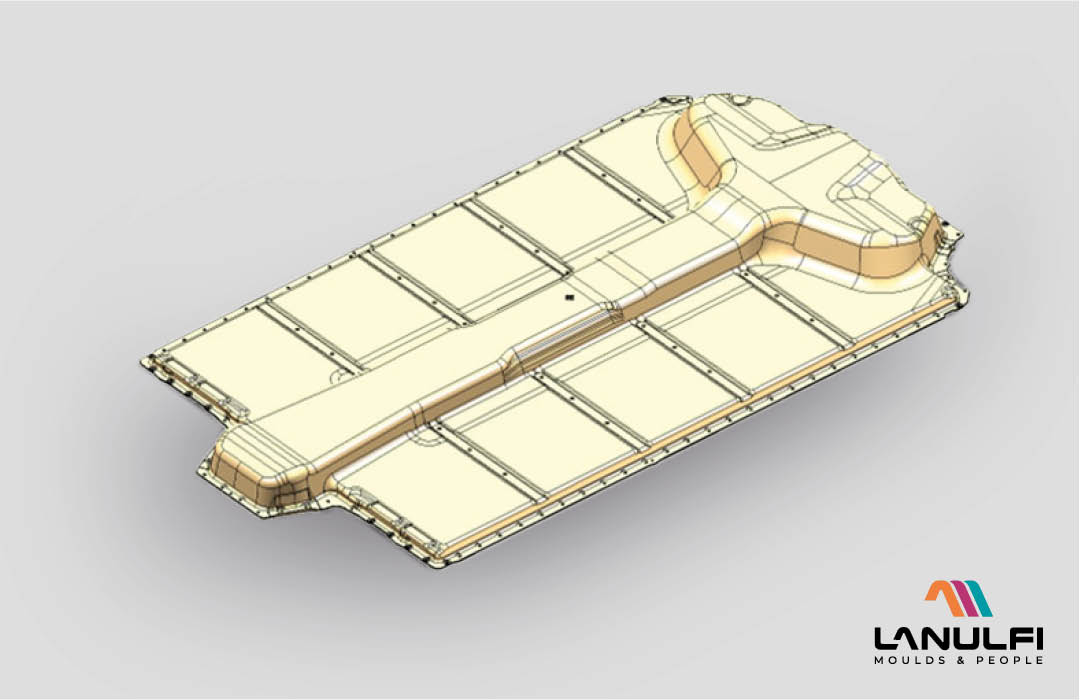

- Automotive: Luggage box, battery cover, sub-engines.

- Agromechanical: grids, parts of hoods, paneling, etc.

- Design: chairs, tables, design objects, etc.

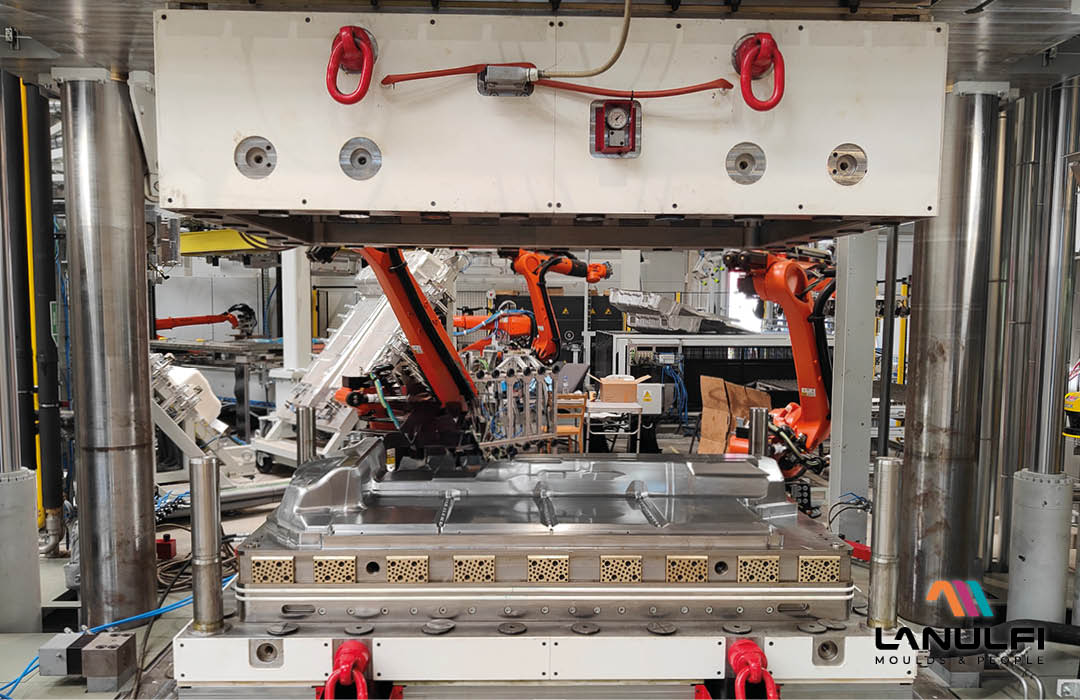

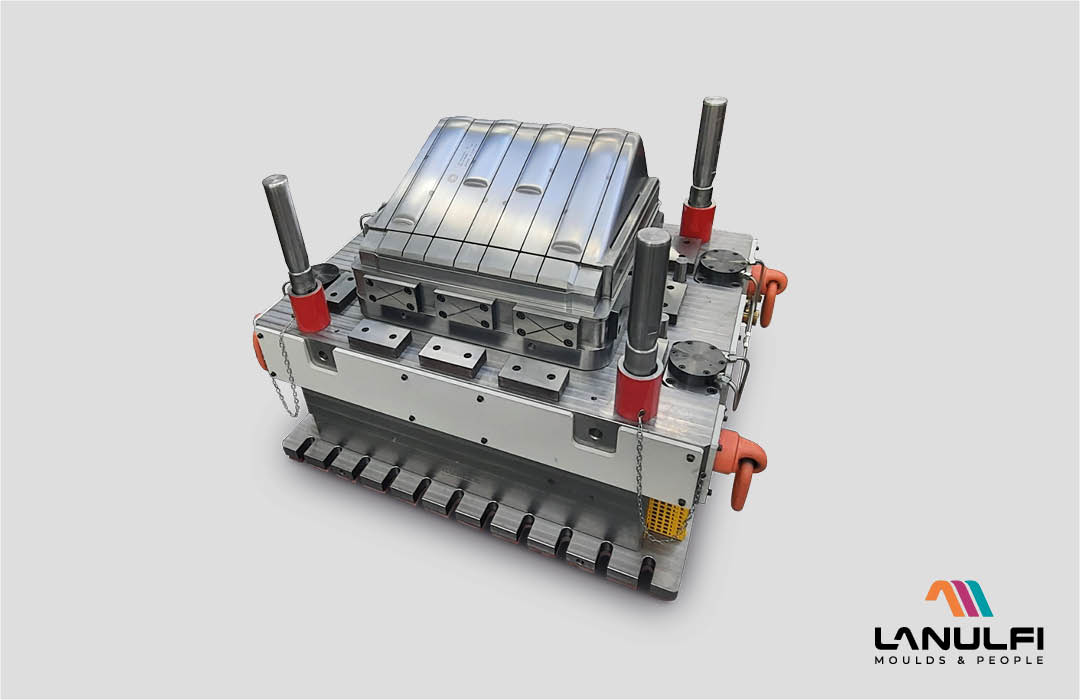

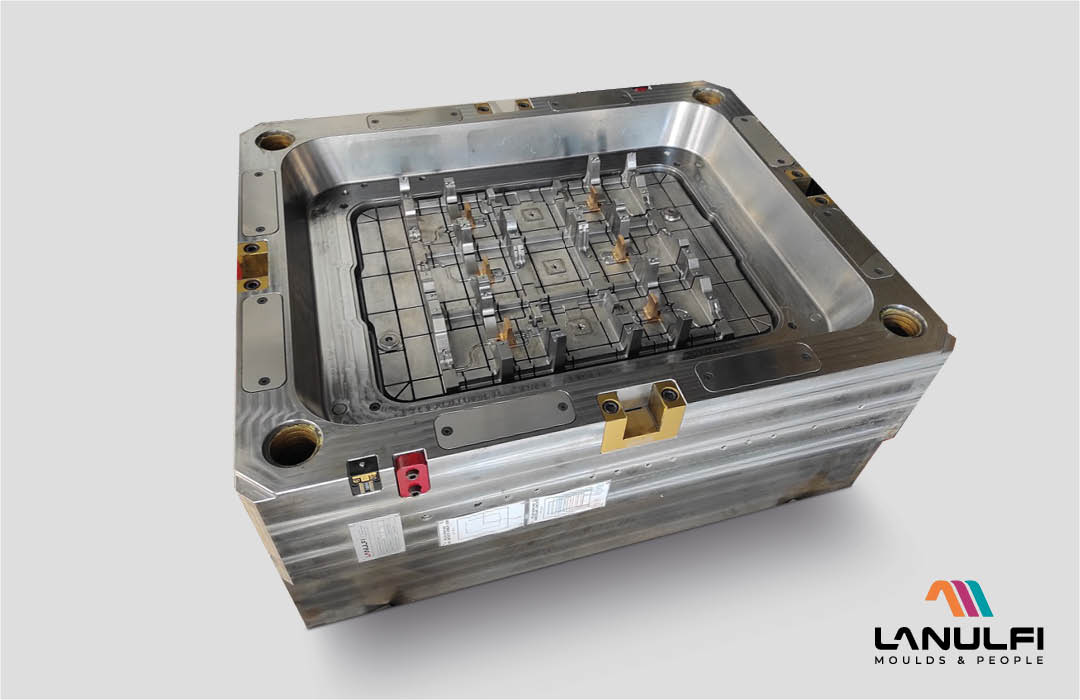

Examples of completed projects

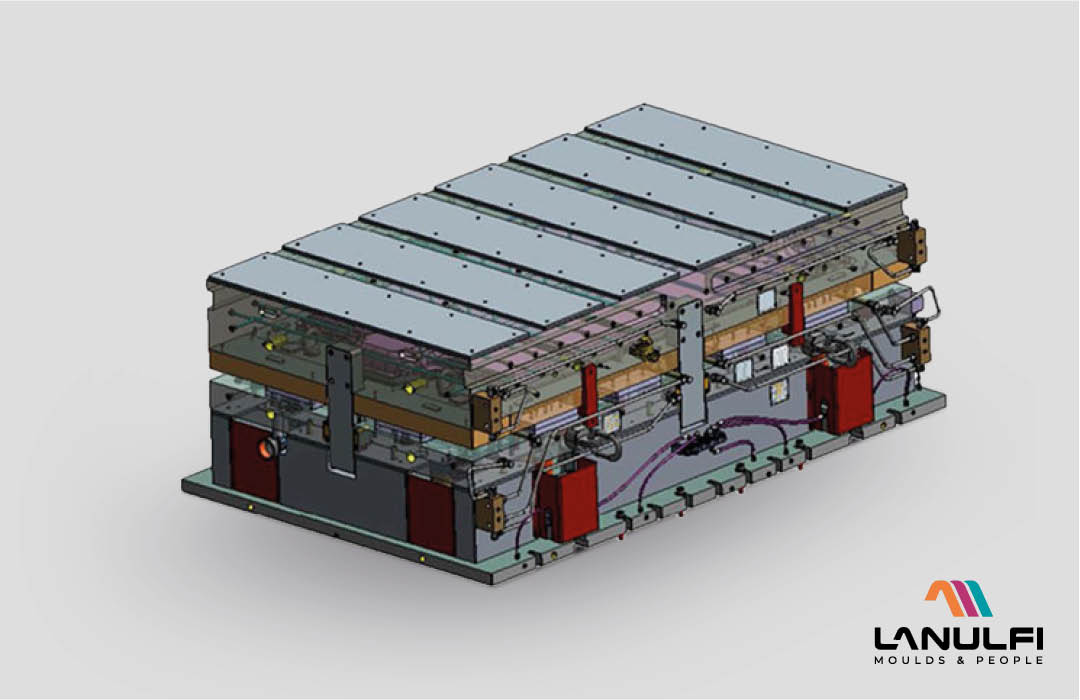

Moulds and compression, dflt, lwrt

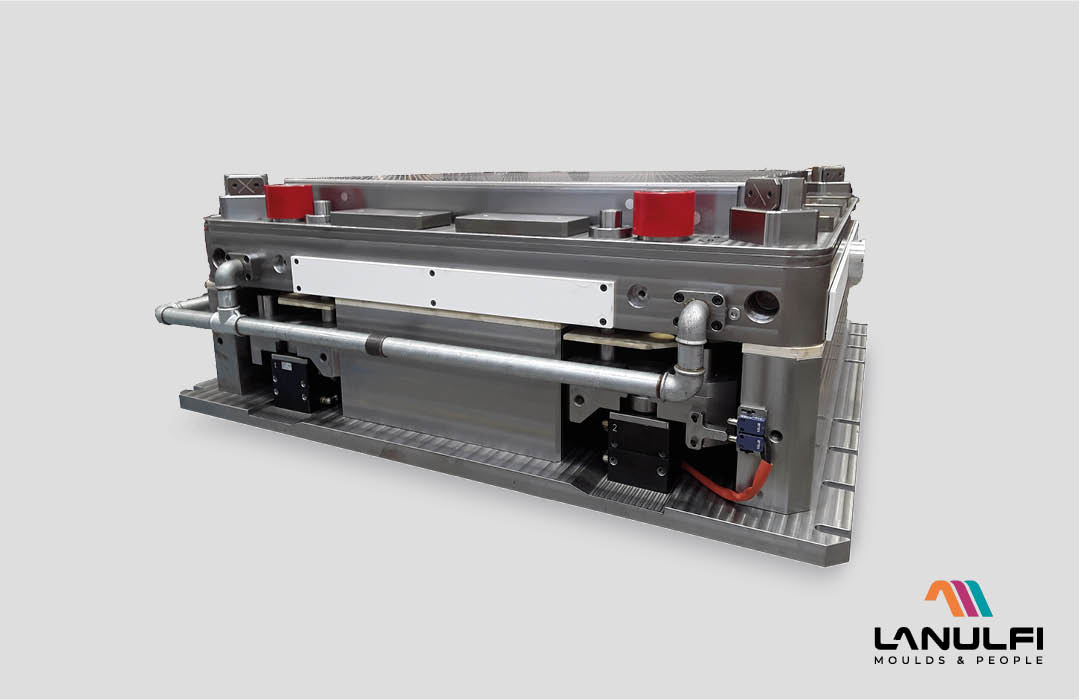

Thermoplastic injection moulds

In the injection mould industry, Lanulfi Company is able to provide its customers with very professional support that includes:

- co-design, and mould design

- structural and mouldflow analysis

- construction of prototype and series moulds

- sampling and small production runs

- dimensional testing

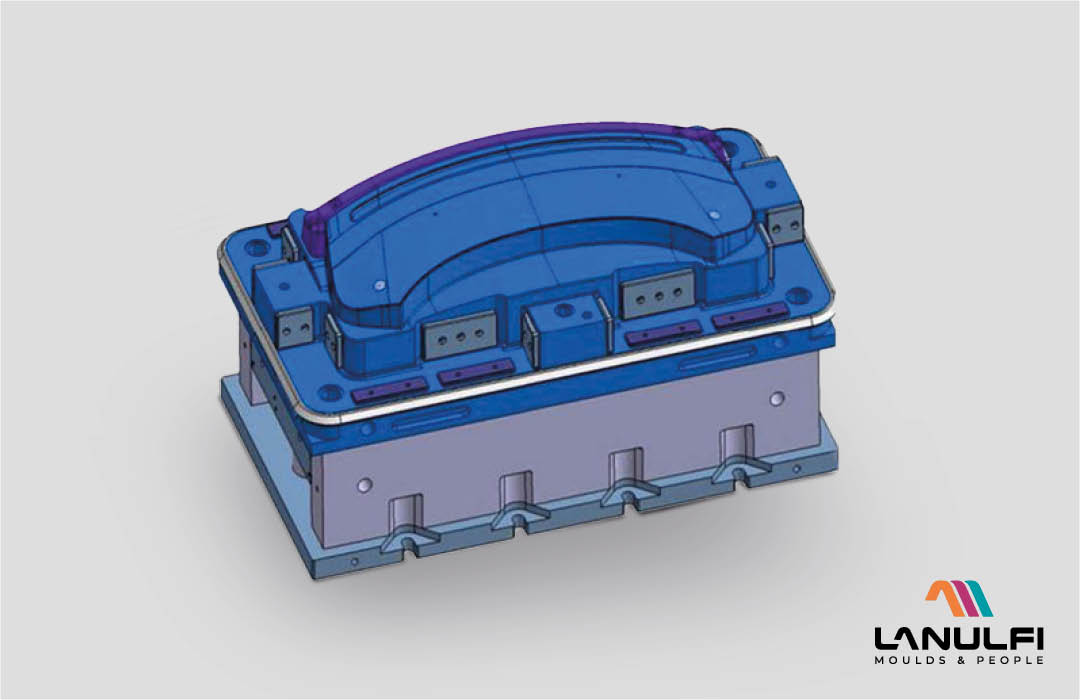

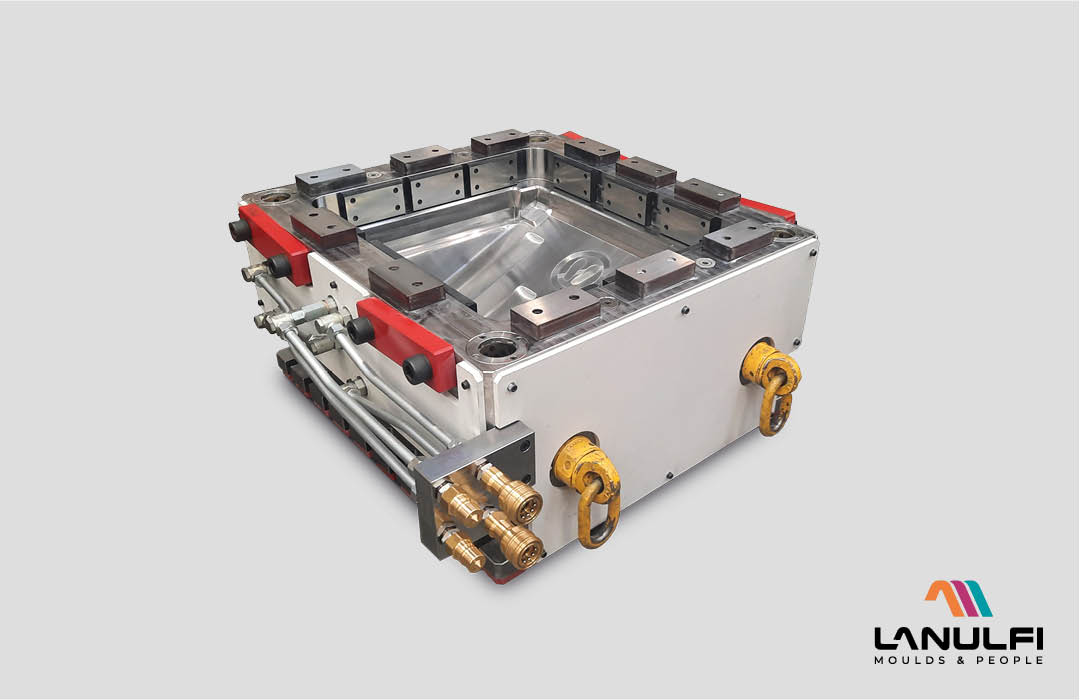

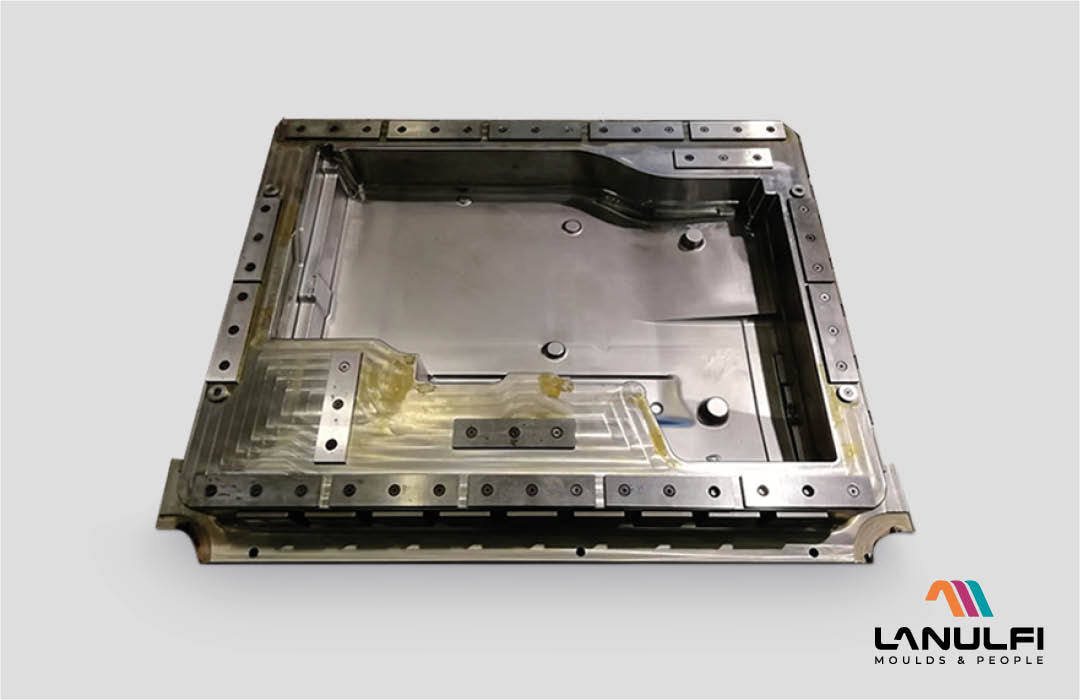

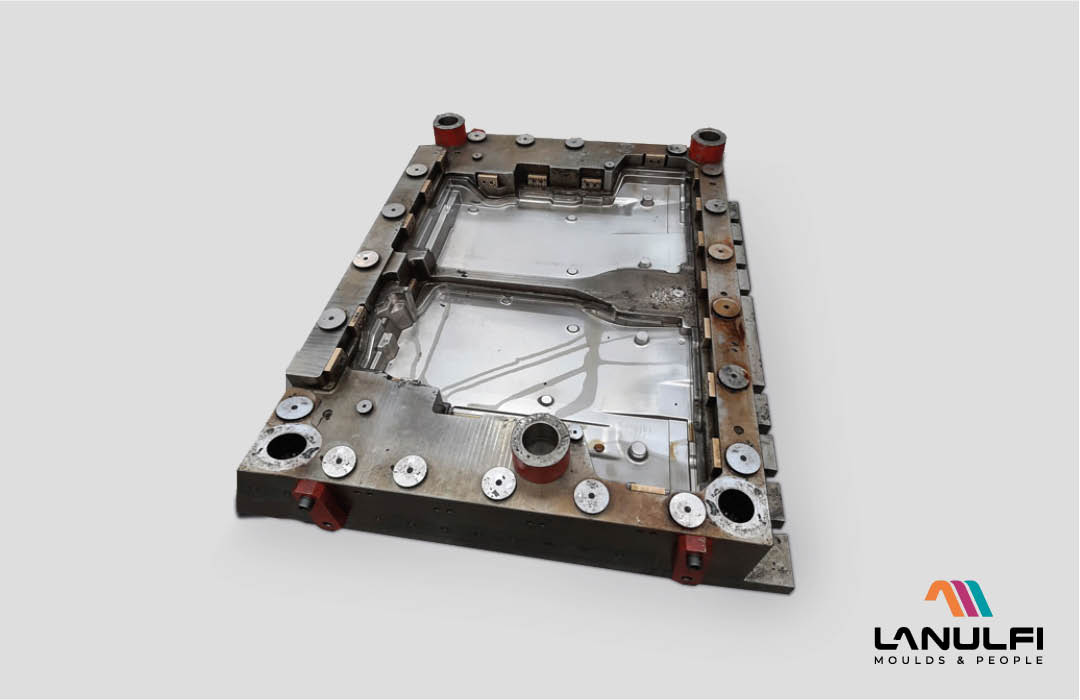

Examples of completed projects

Special equipment

WE ARE ALWAYS READY

TO HELP YOU

Would you like more information or a new project? Contact us by filling in the following form.