Lanulfi Moulds

Reliability and productivity guaranteed by Lanulfi’s moulds of excellence.

The design and processing of thermoset or thermoplastic moulds, thermoforming, and rotational moulds is a highly specialized discipline that requires advanced technical skills and in-depth knowledge of materials and their properties. Aluminum is an ideal material for creating moulds for these production technologies because of its exceptional strength, light weight and thermal conductivity characteristics.

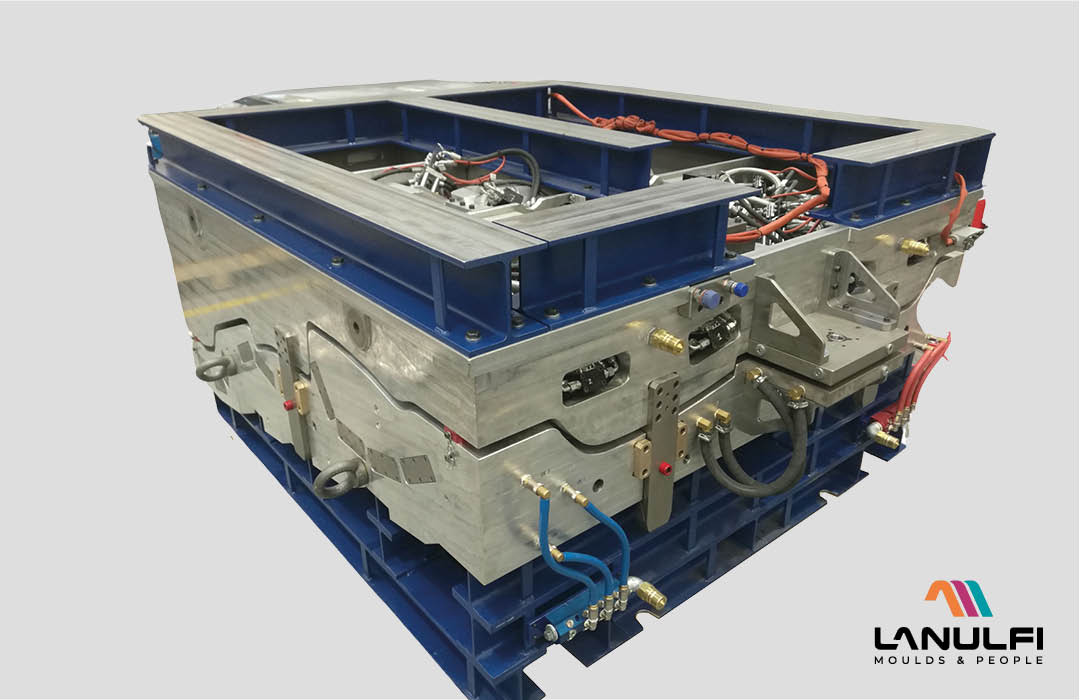

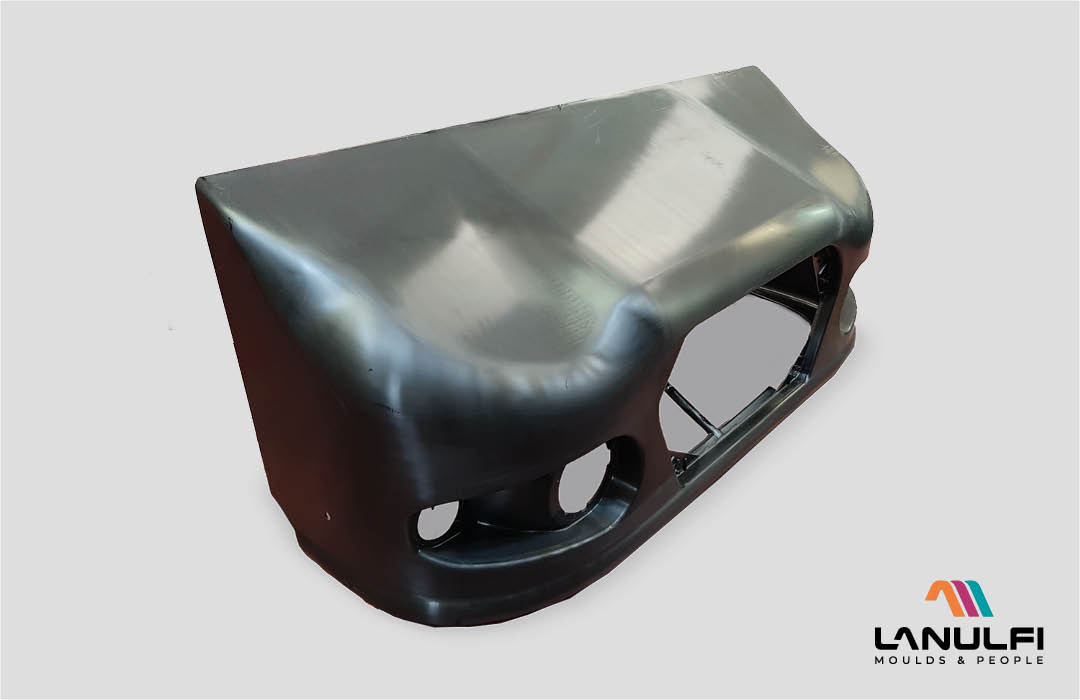

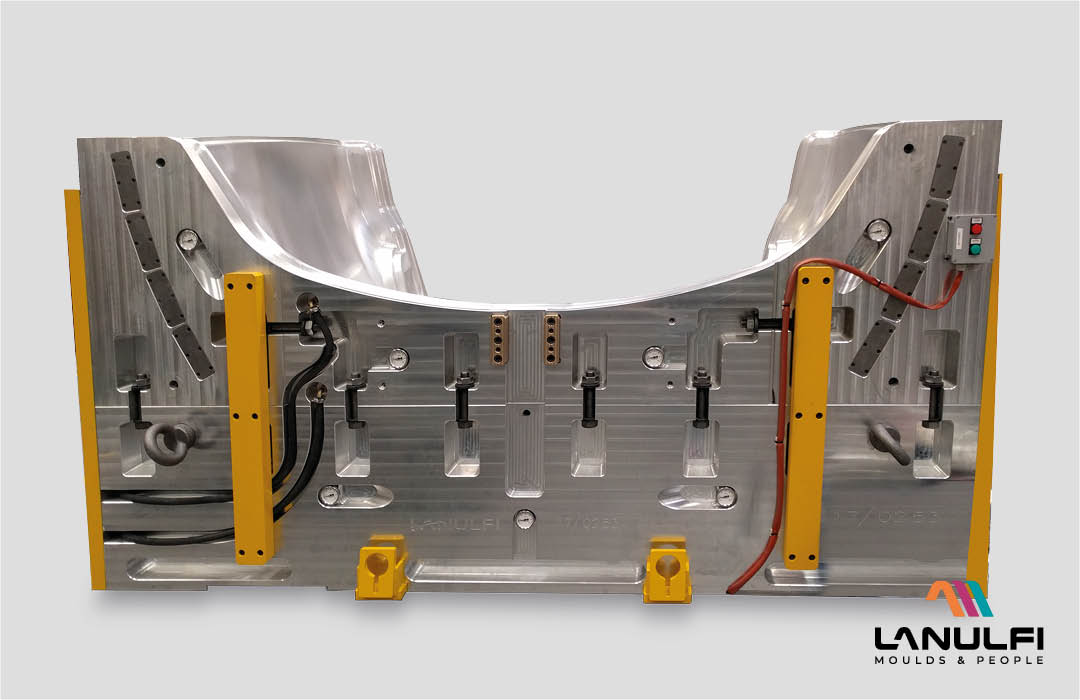

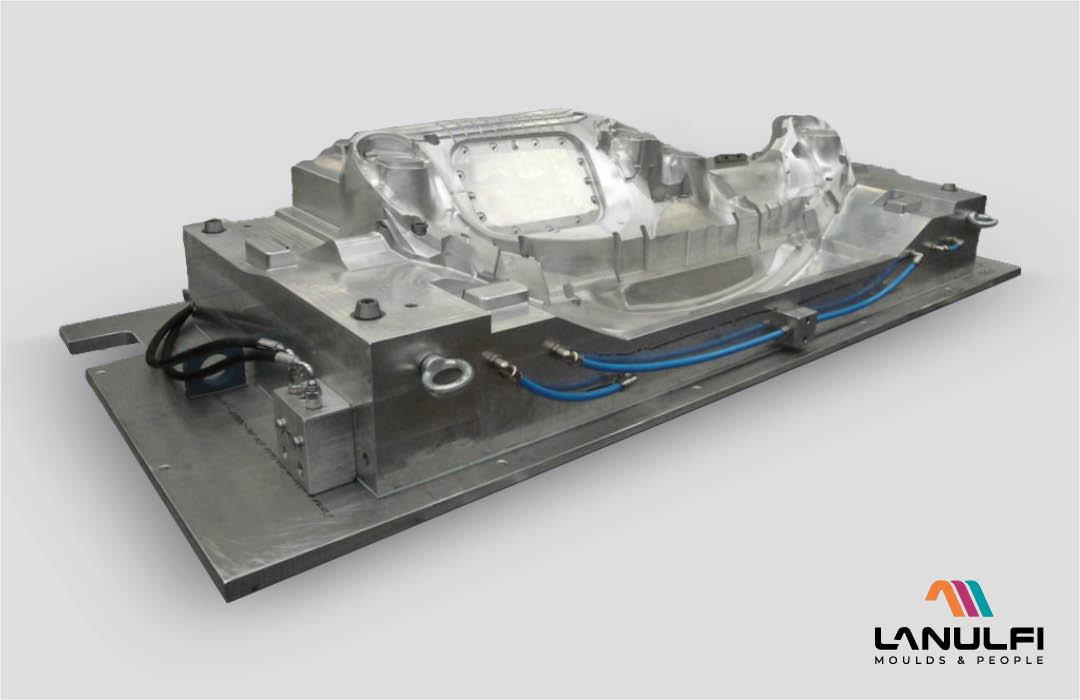

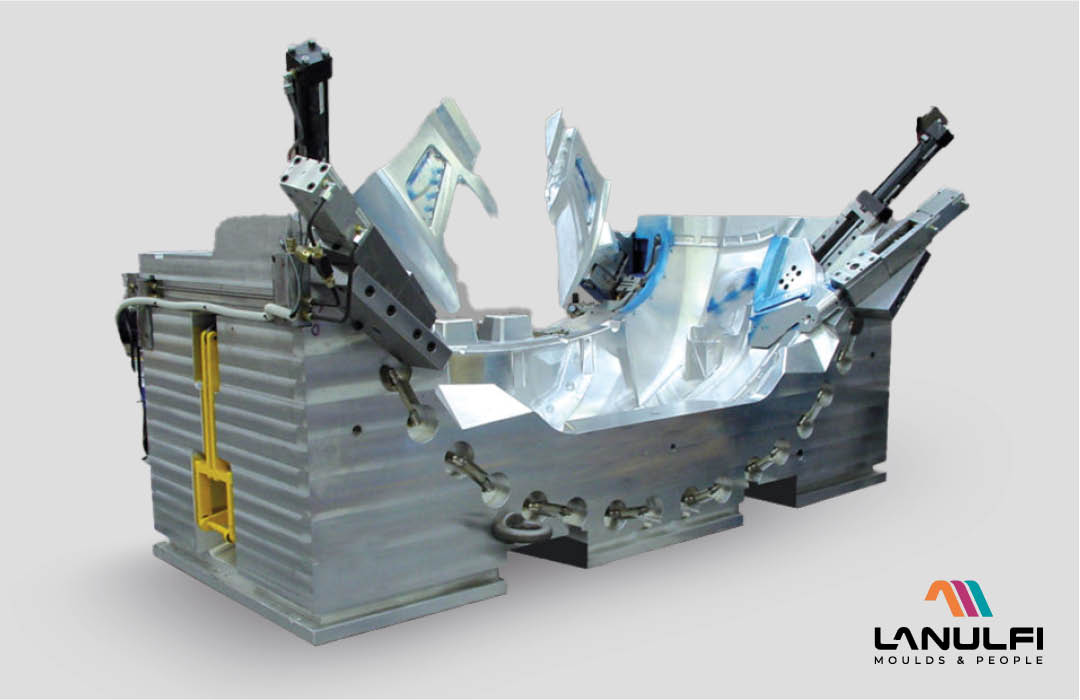

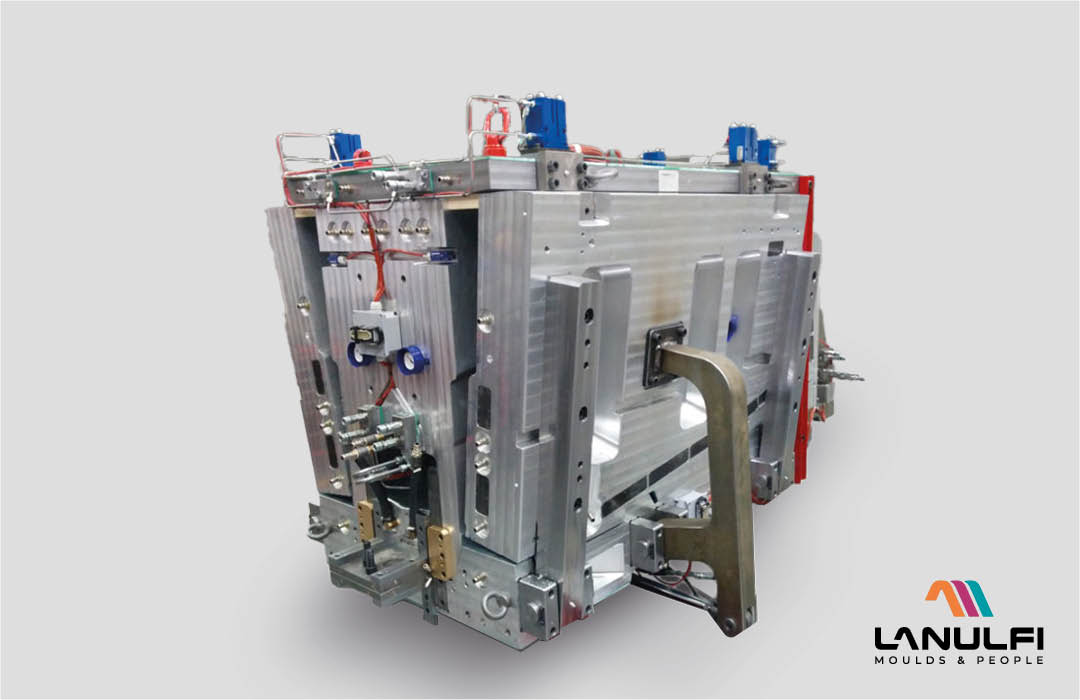

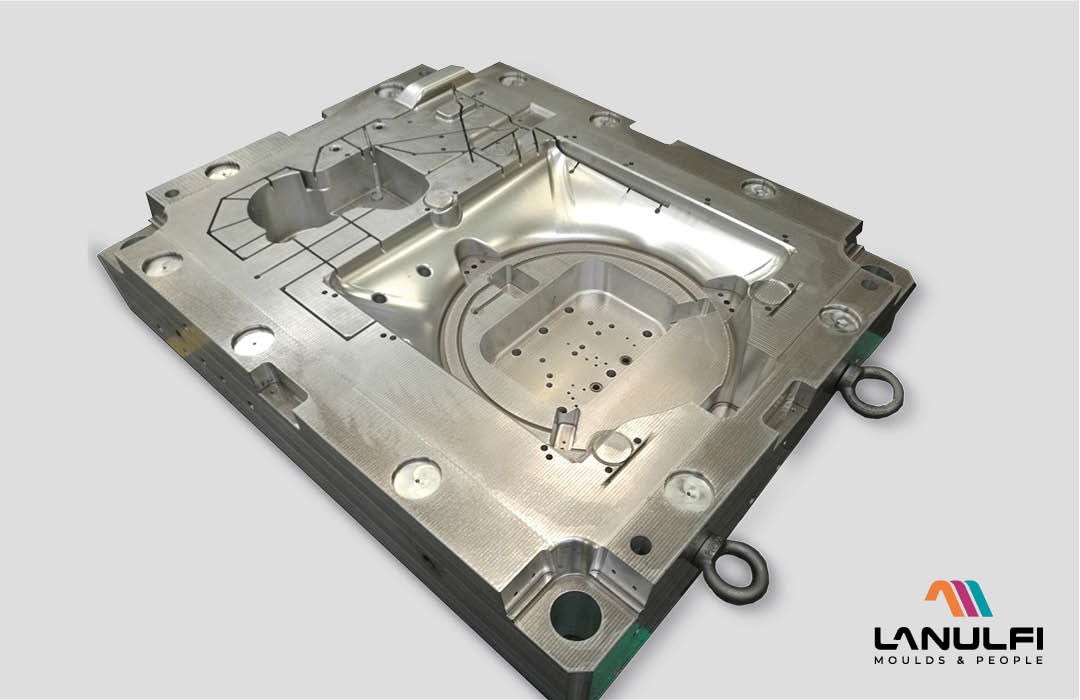

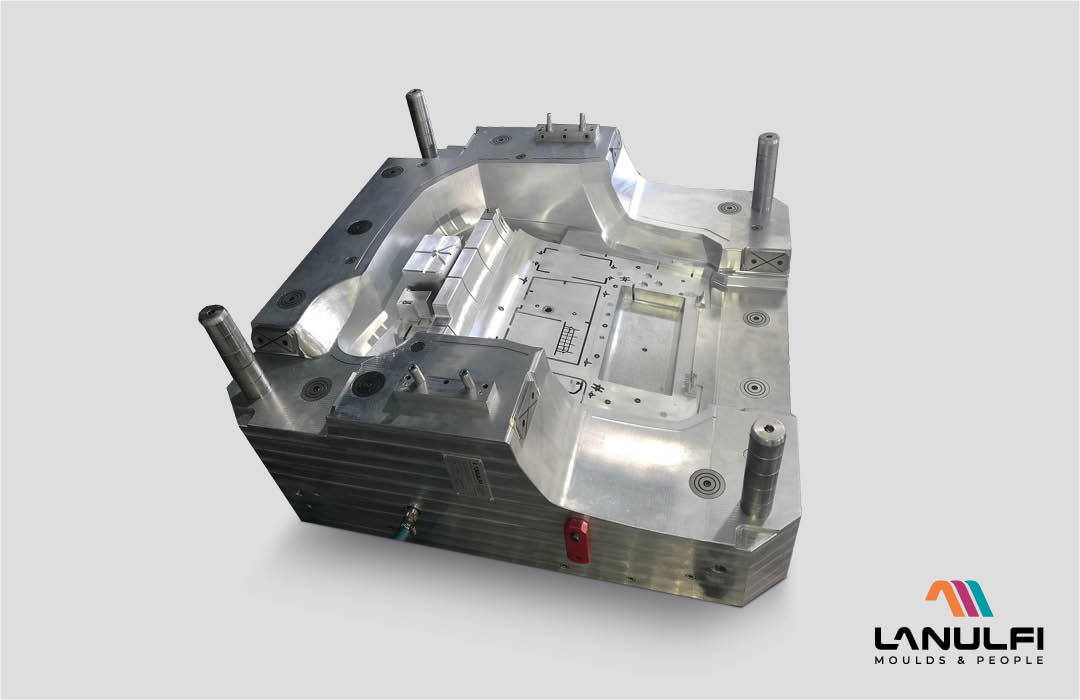

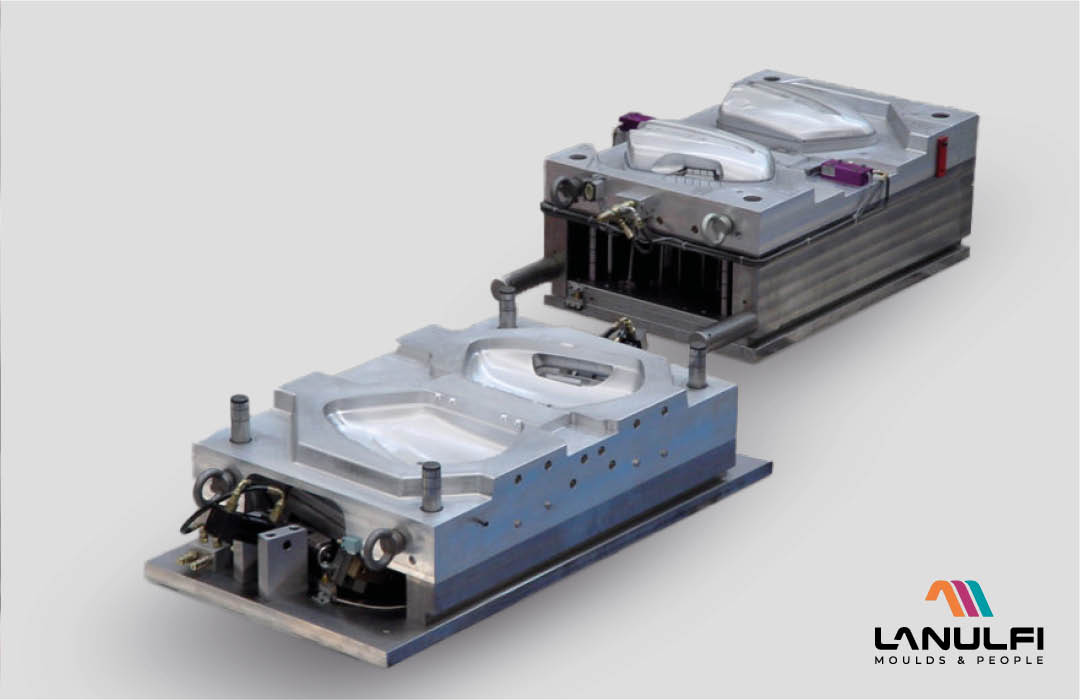

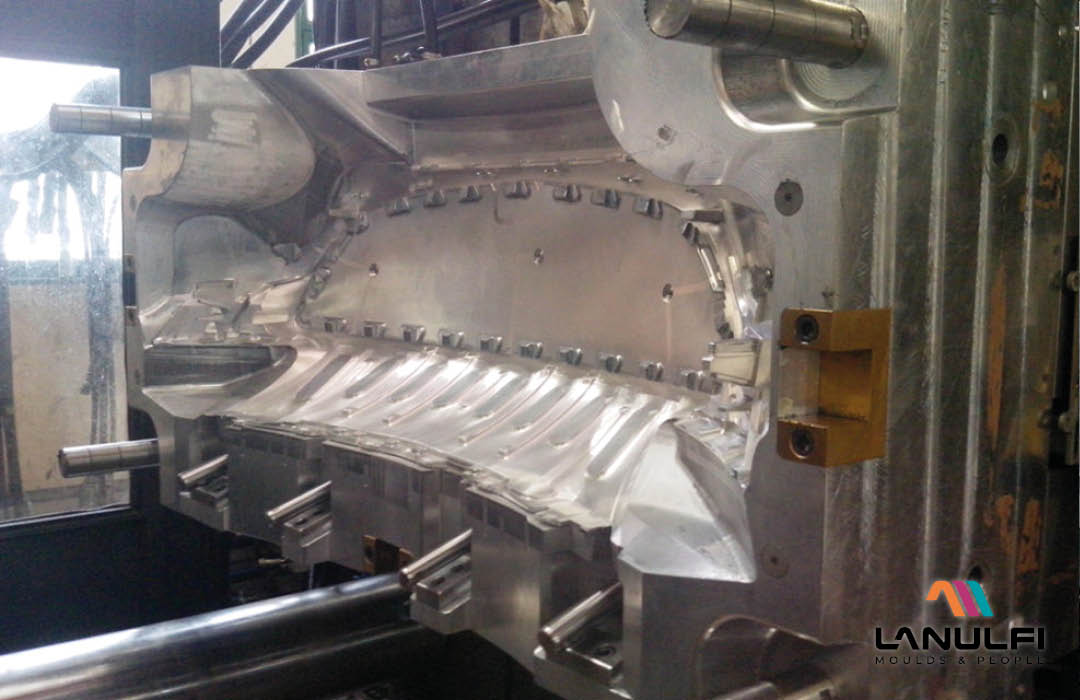

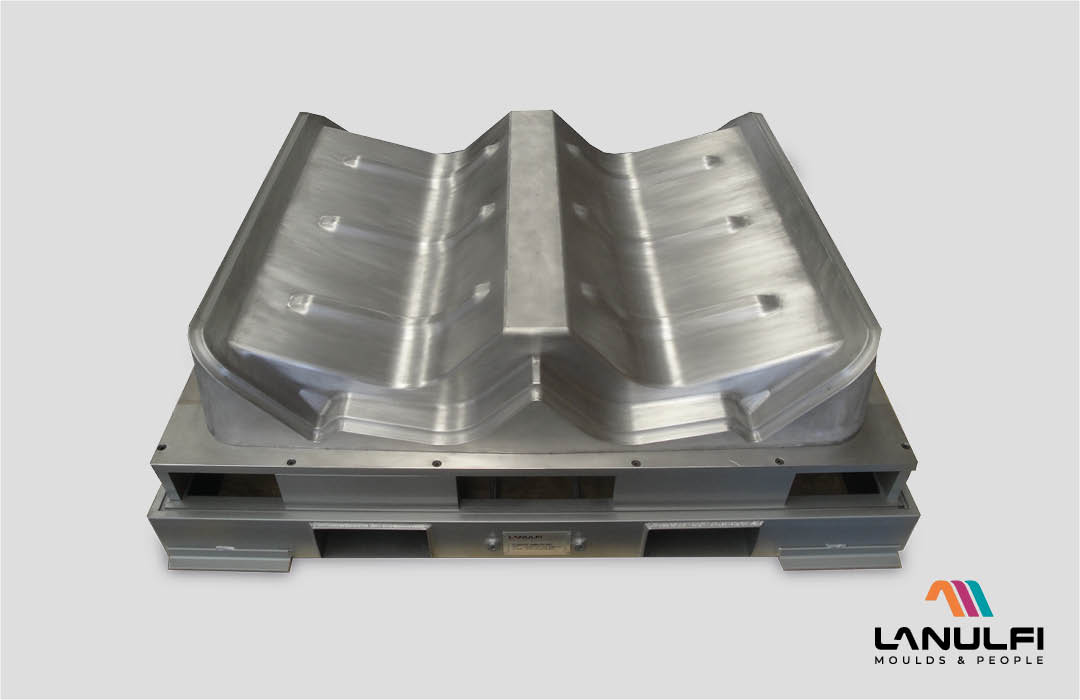

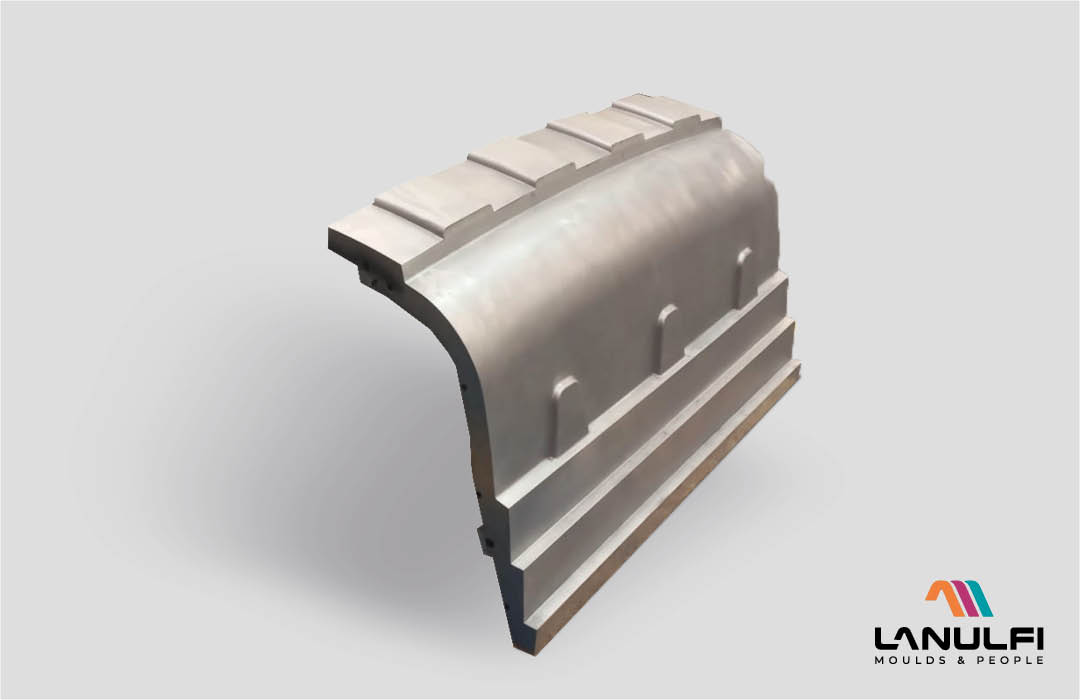

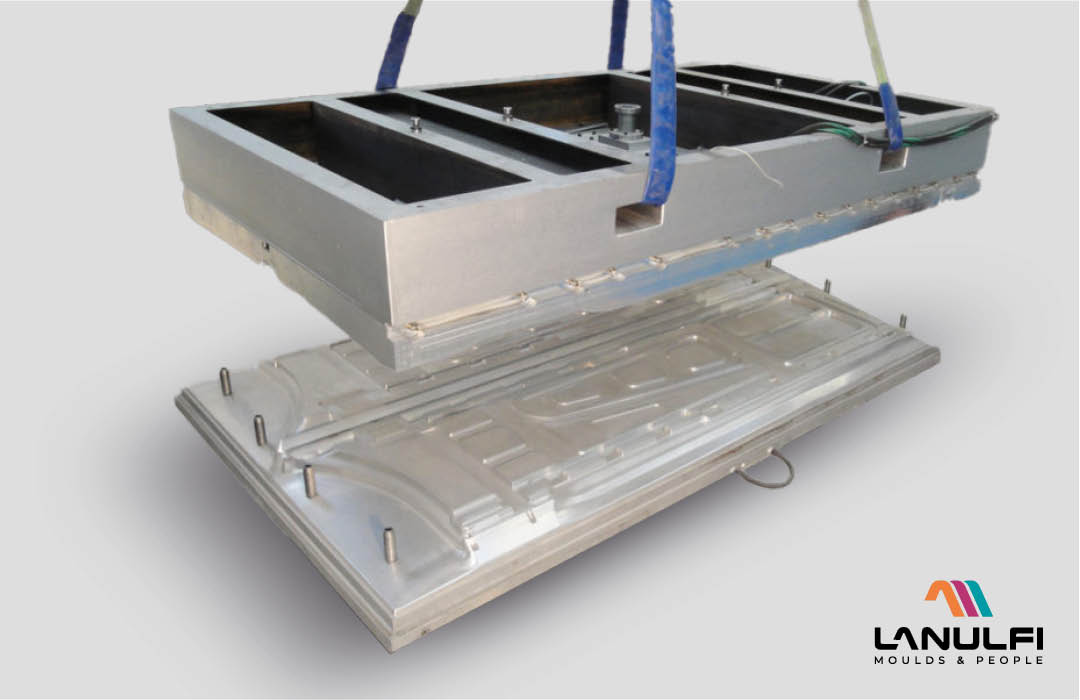

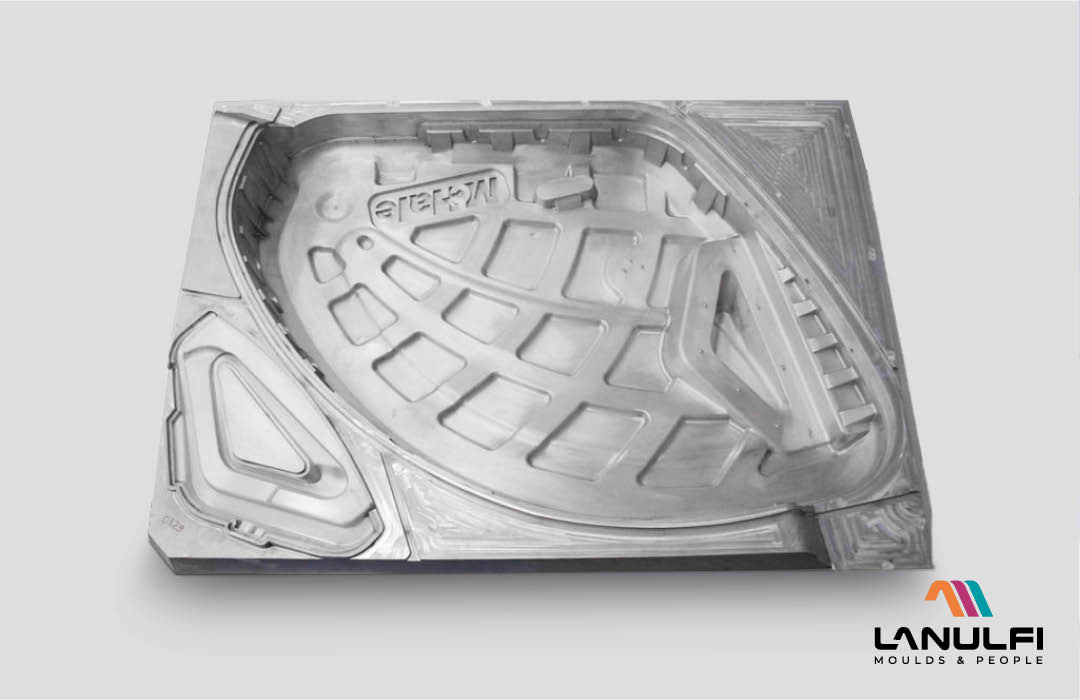

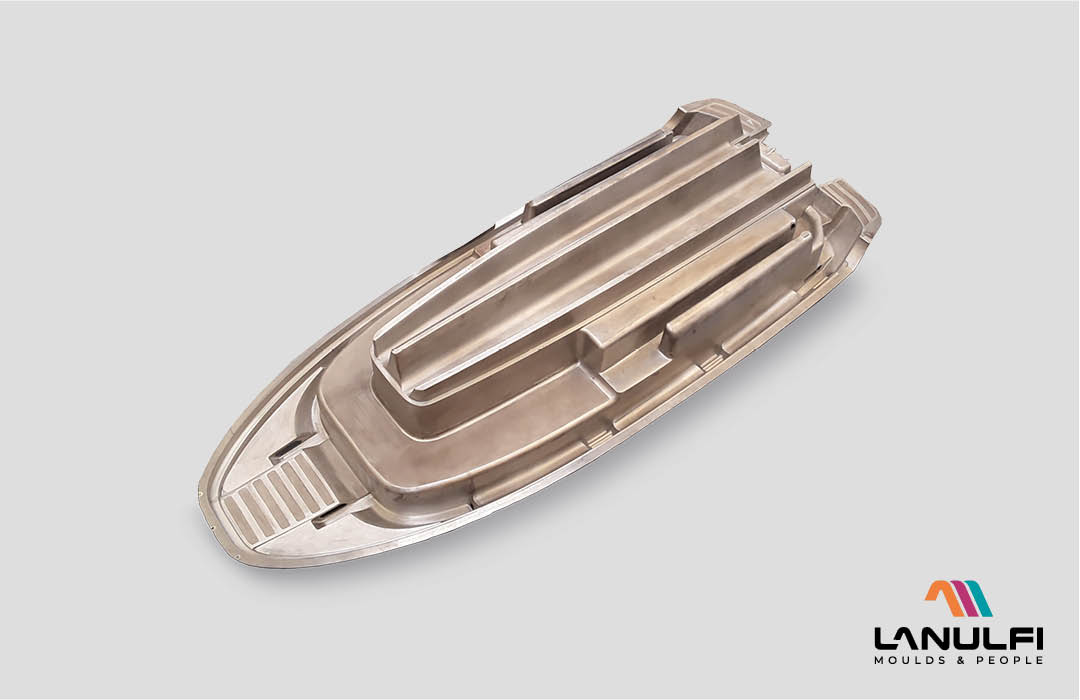

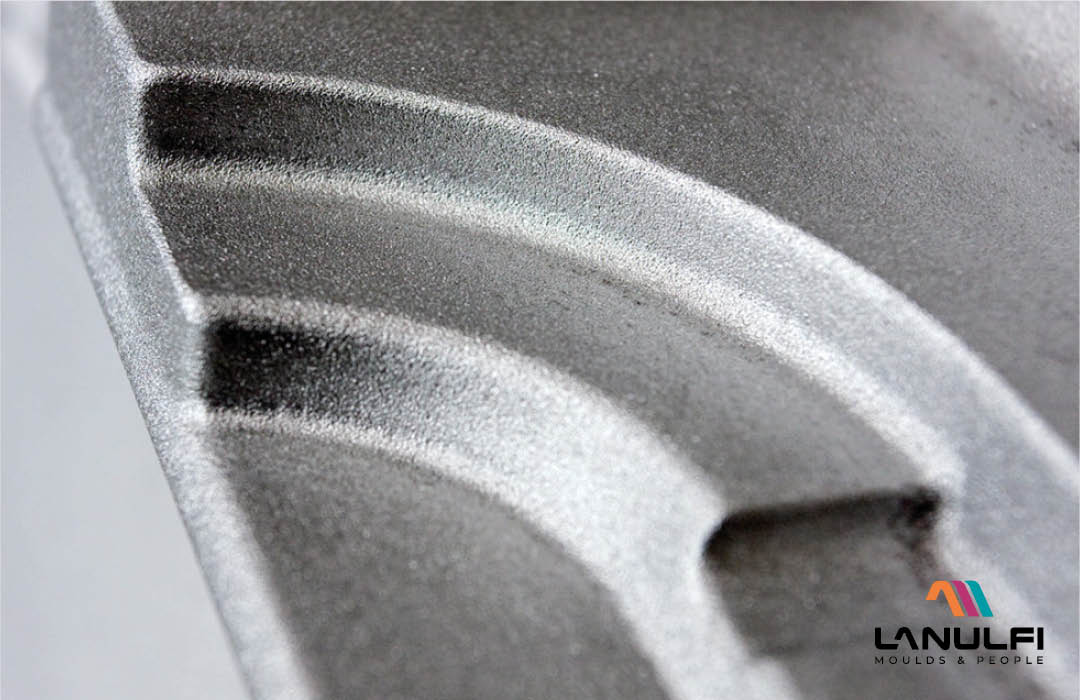

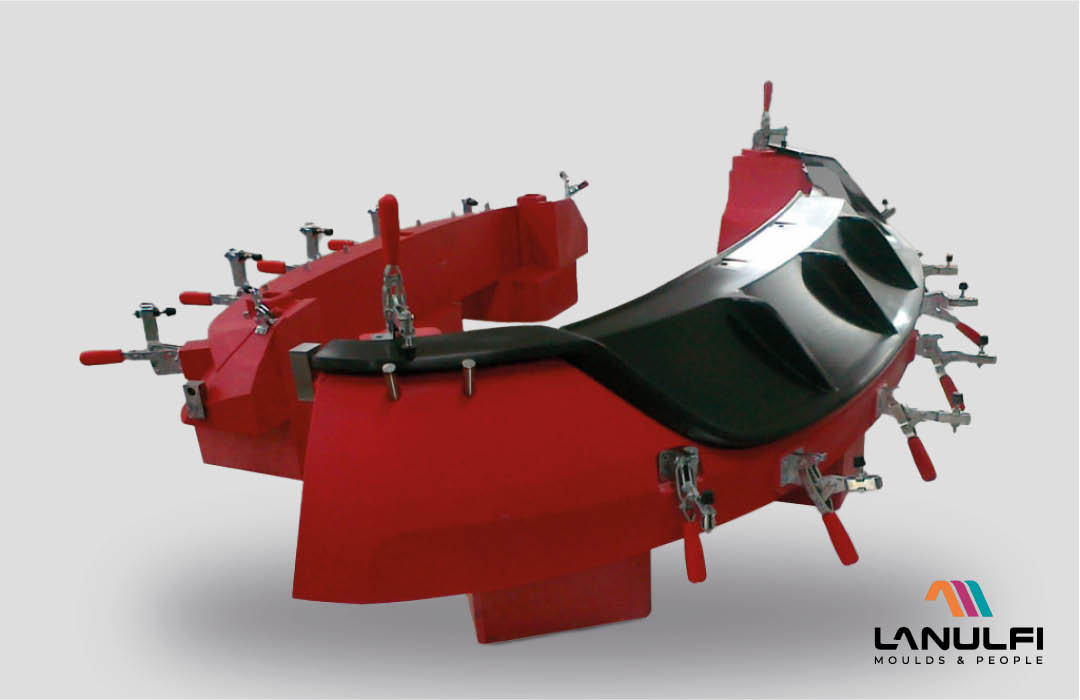

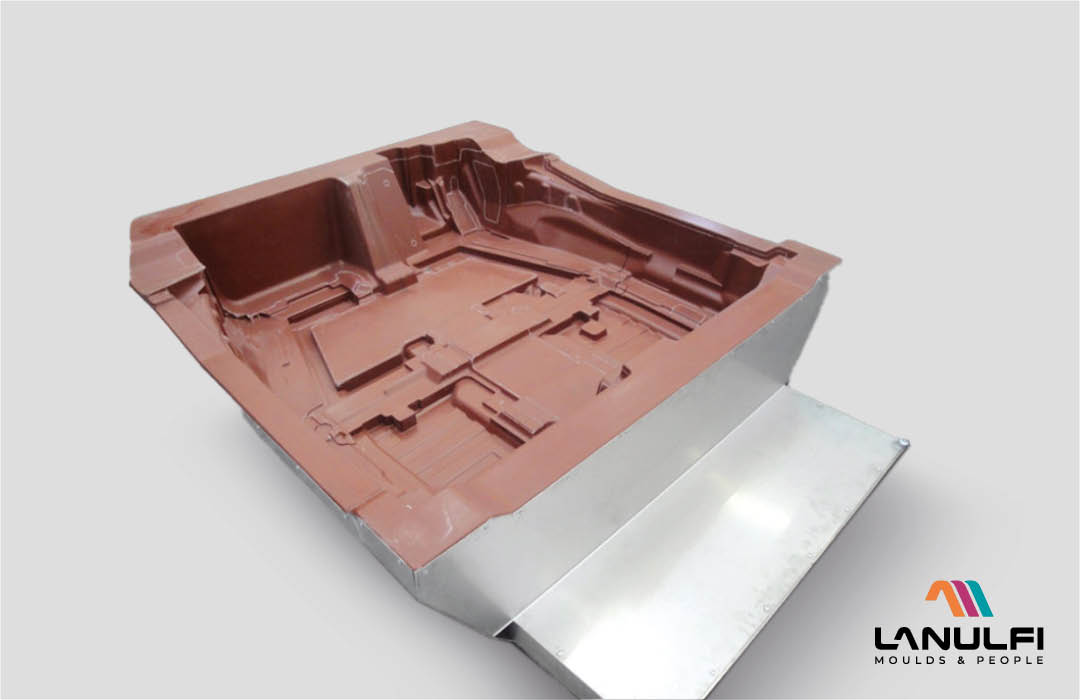

Thermosetting moulds

Lanulfi's long experience in aluminum processing has enabled it to establish itself among the leading companies in mould making for polyurethane resins and composite materials.

We produce moulds made from aluminum blocks or castings for the following technologies: RIM - PUR - RTM - SMC - GMT - PDCPD

TYPES AND SECTORS

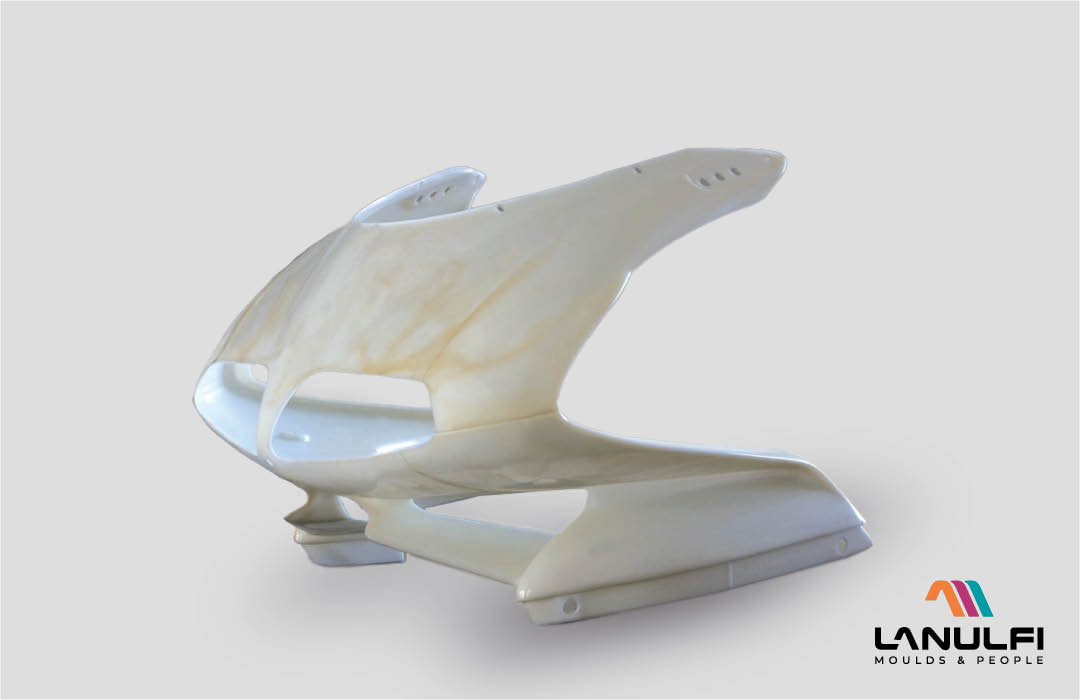

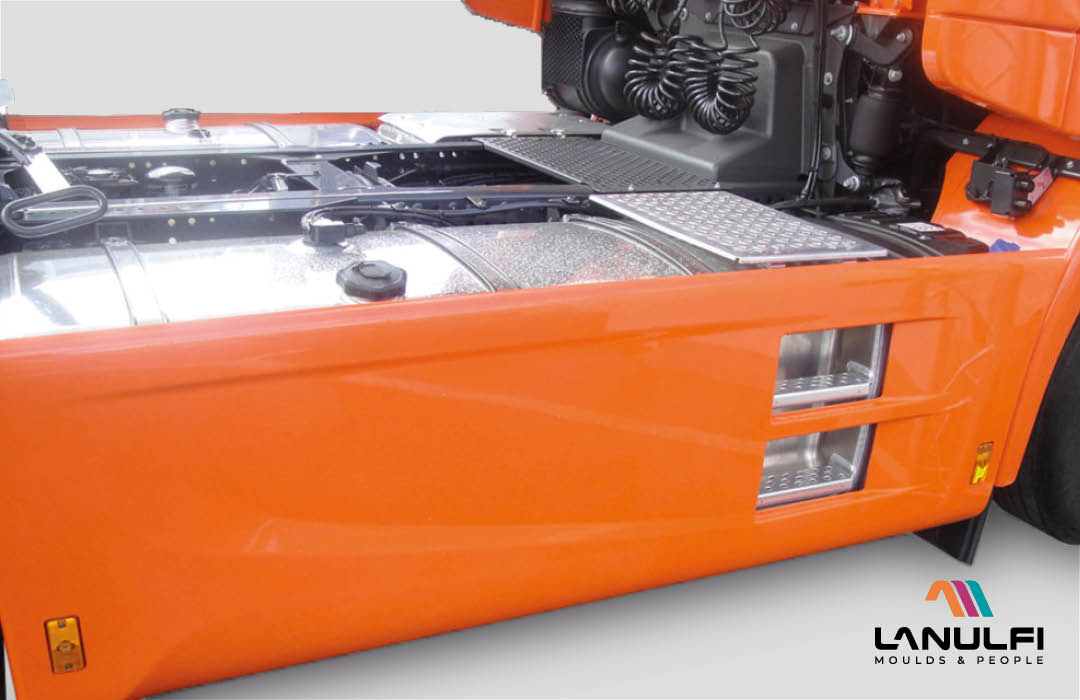

- Automotive: bumpers, dashboards, door panels, fairings, various components, etc.

- Agromechanical: grilles, body parts, etc.

- Medical: supporting structures, hospital furniture, etc.

- Design: chairs, tables, design objects, etc.

Examples of completed projects

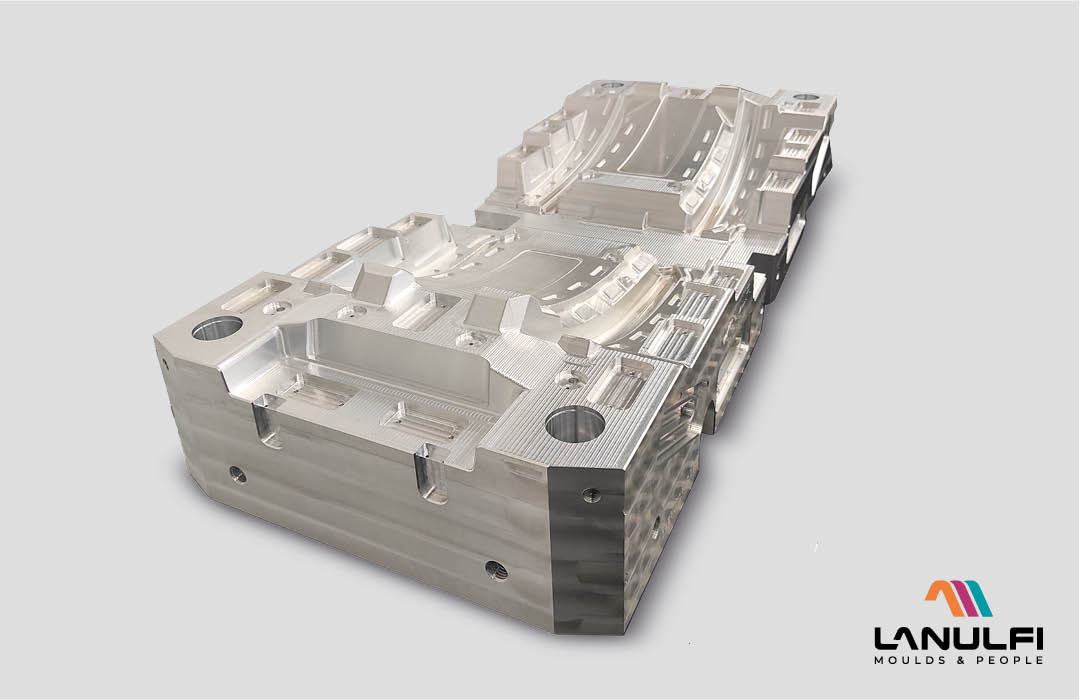

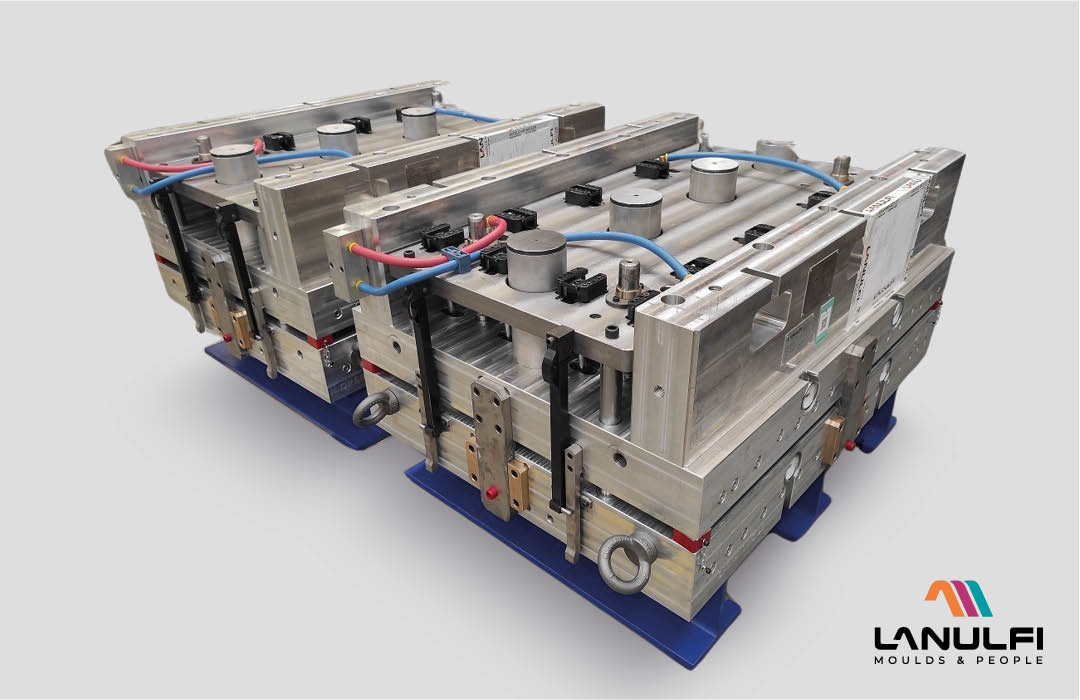

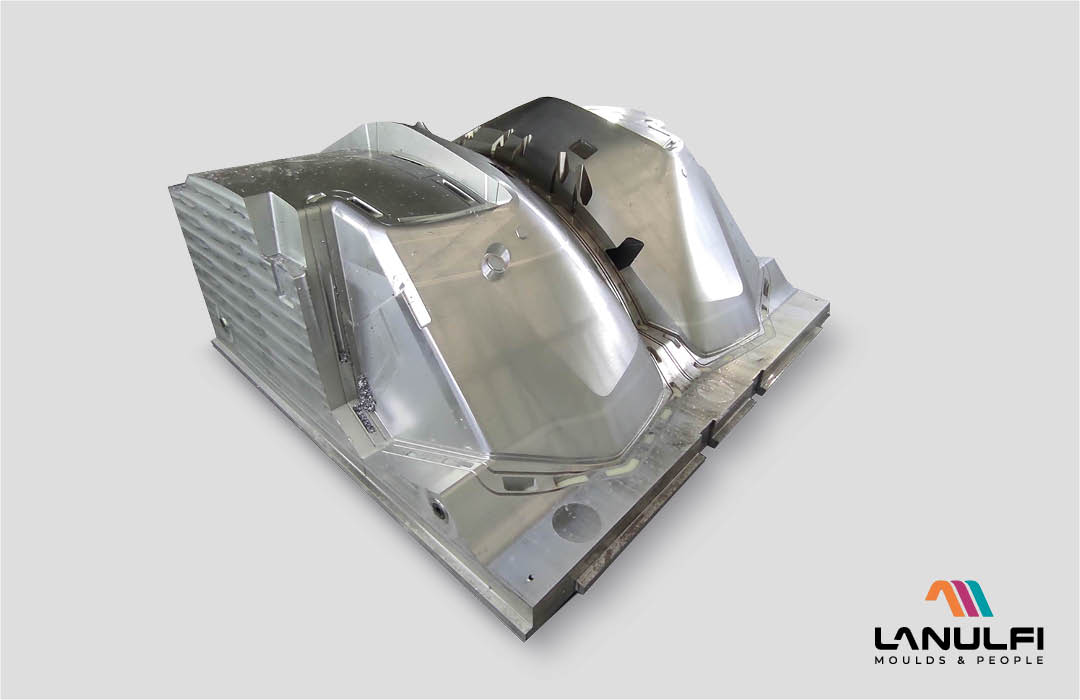

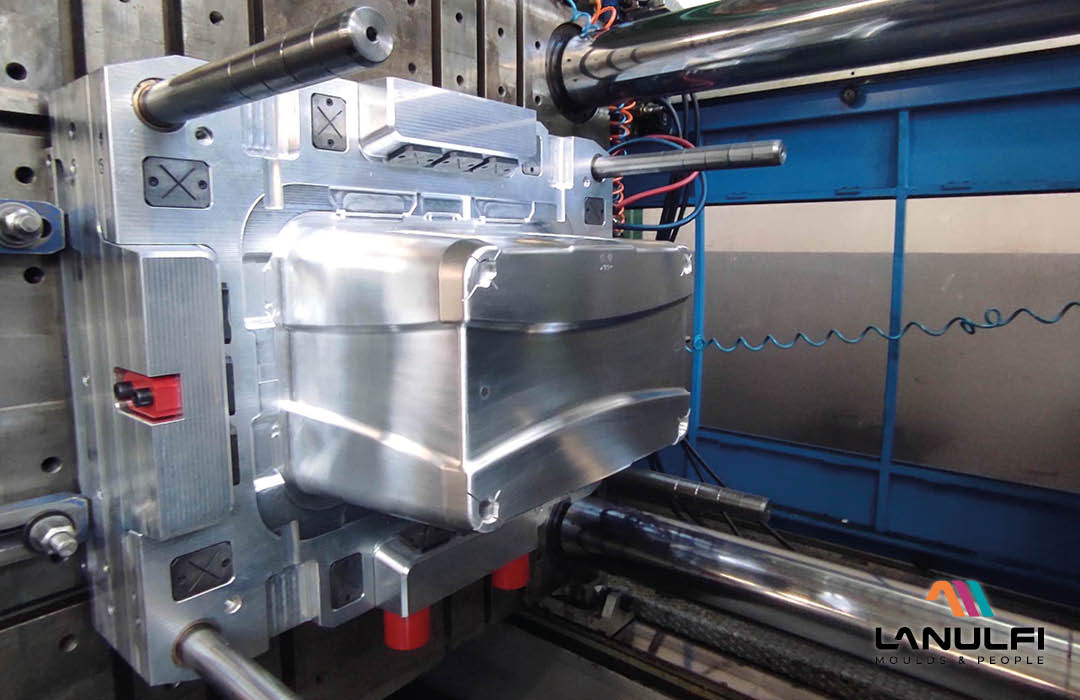

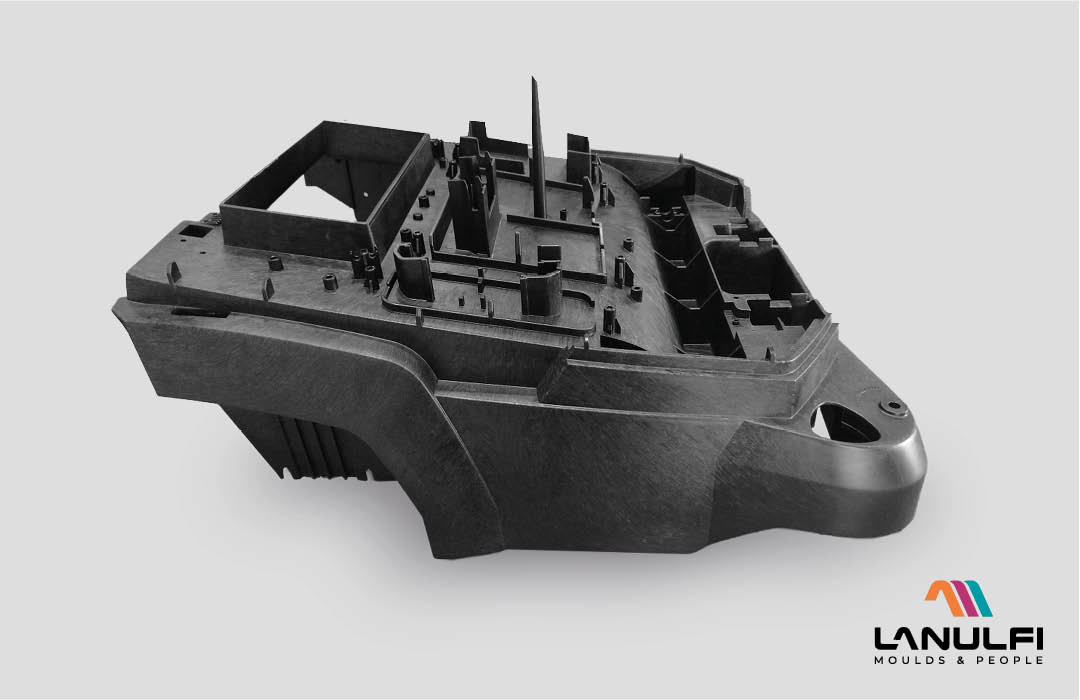

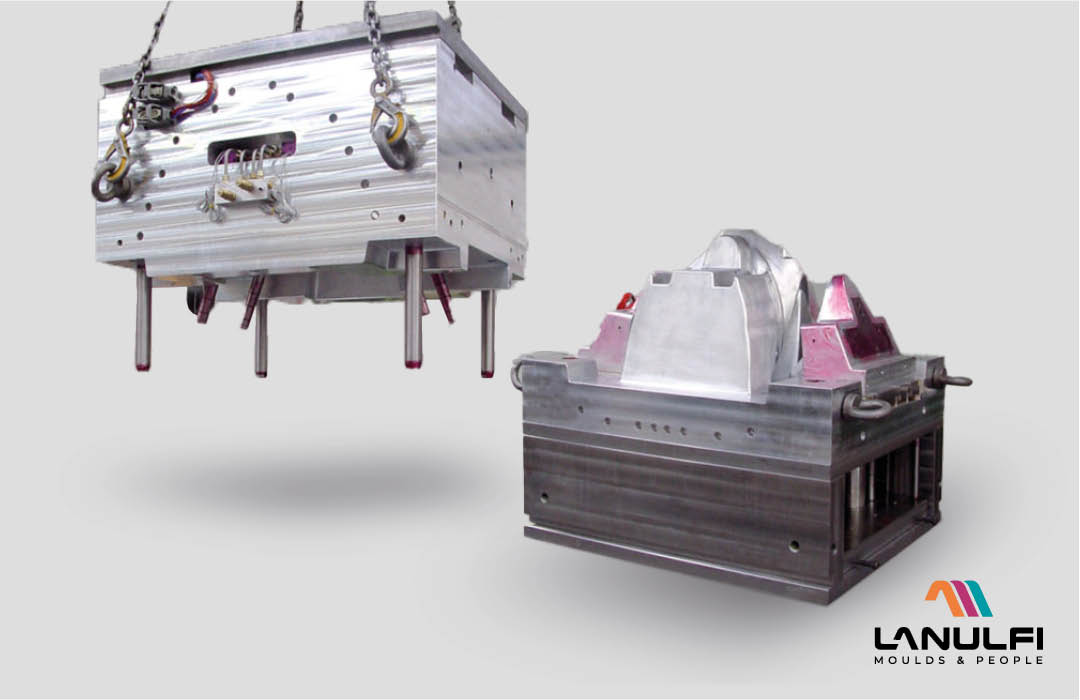

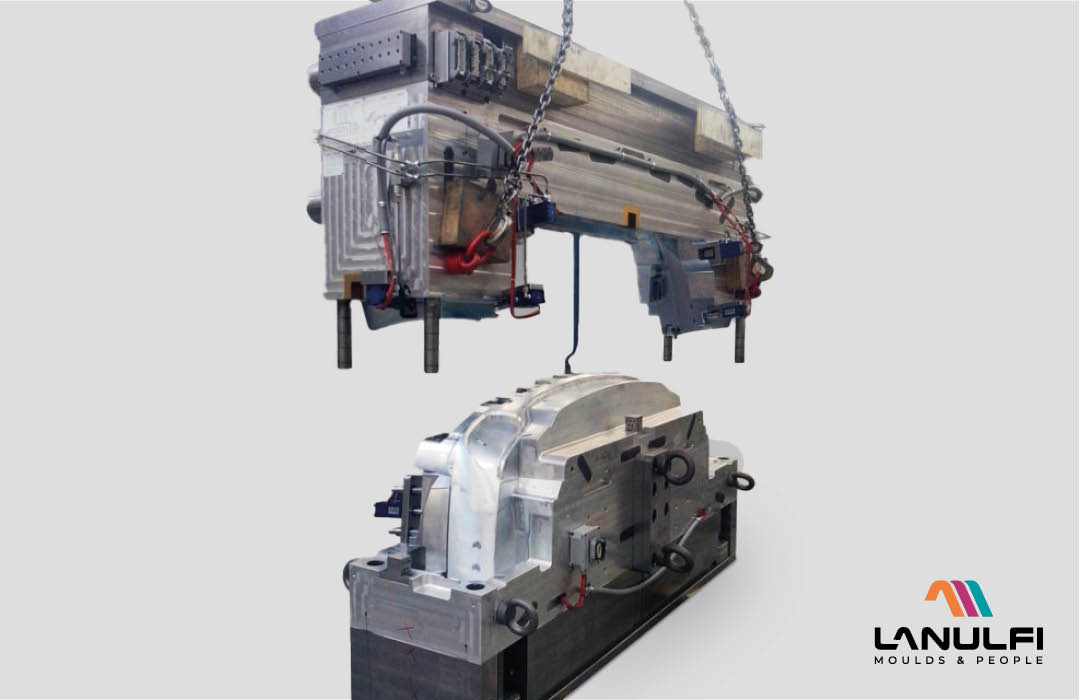

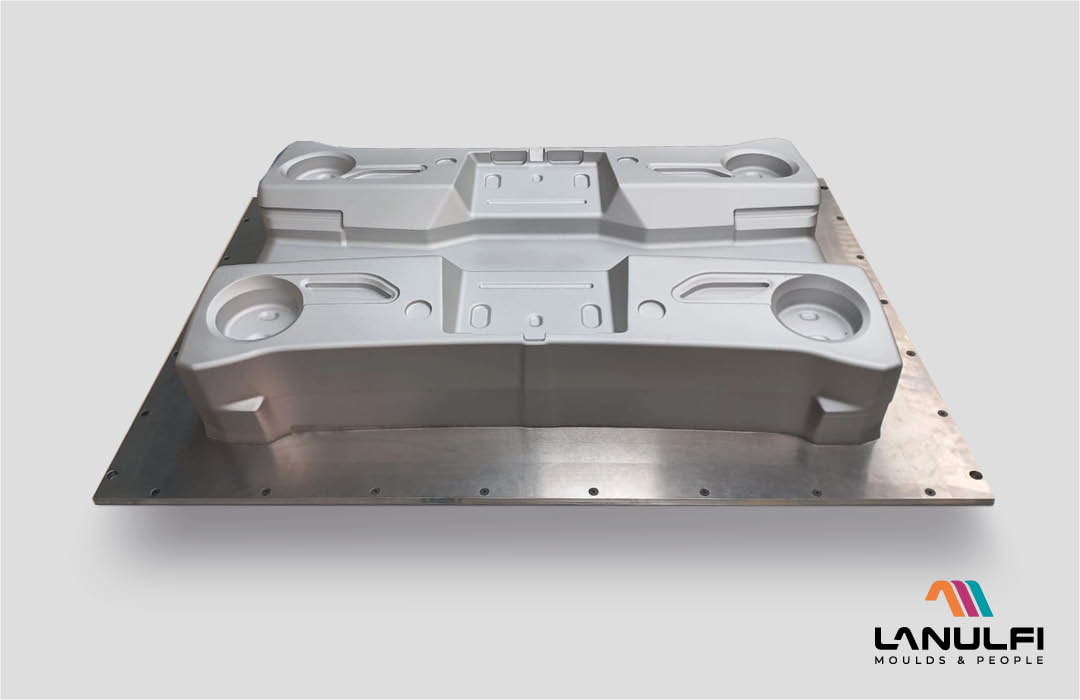

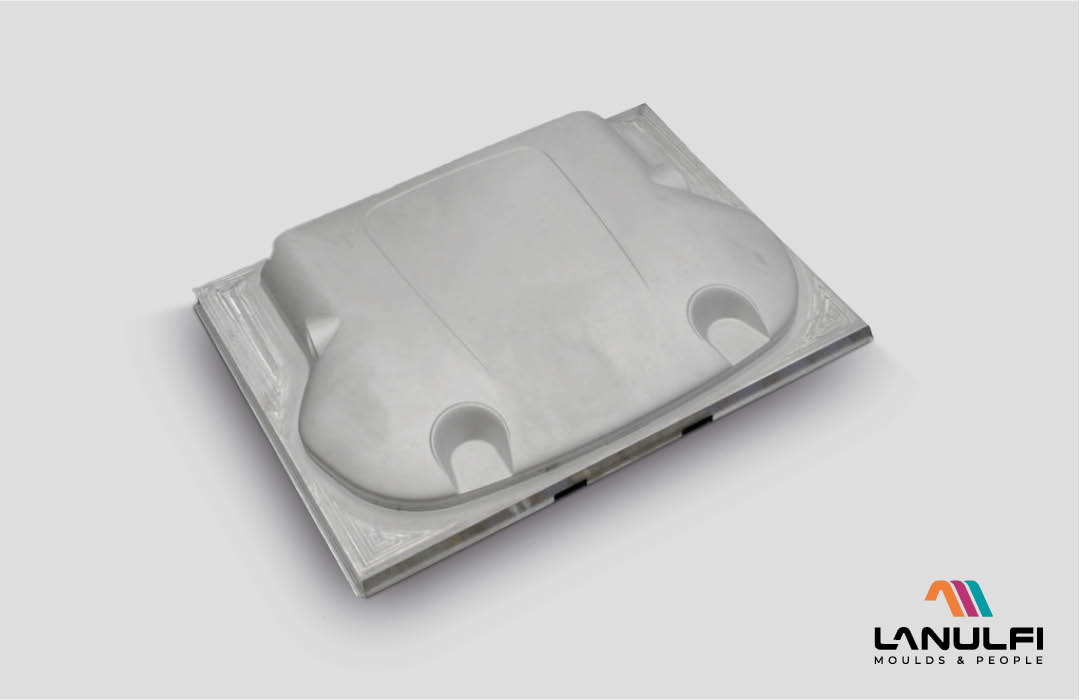

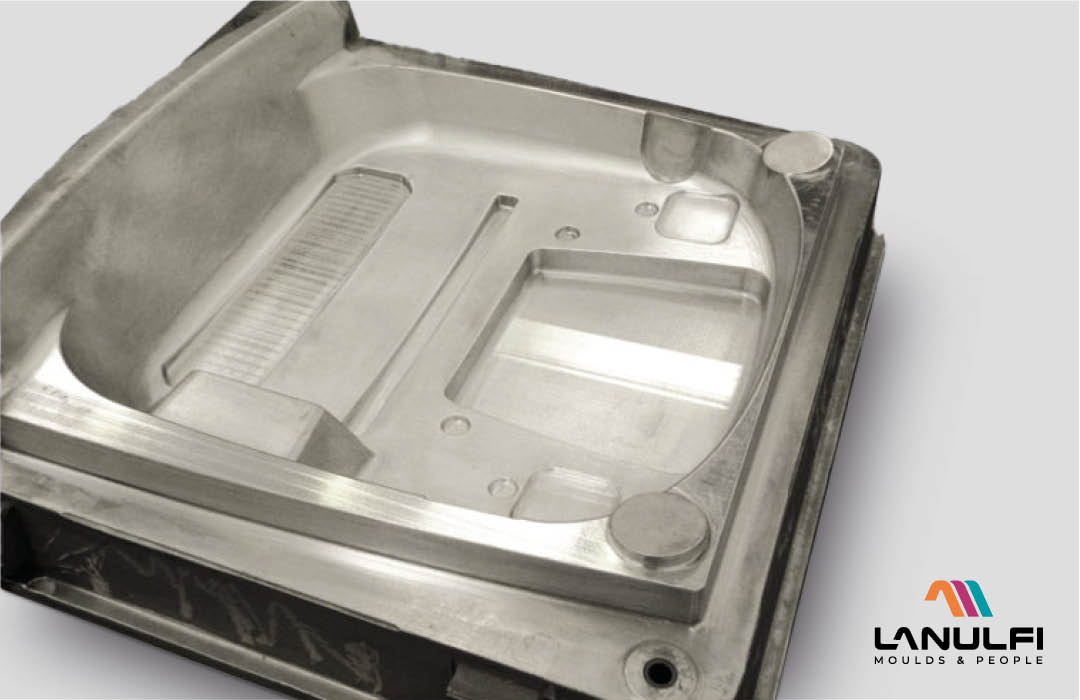

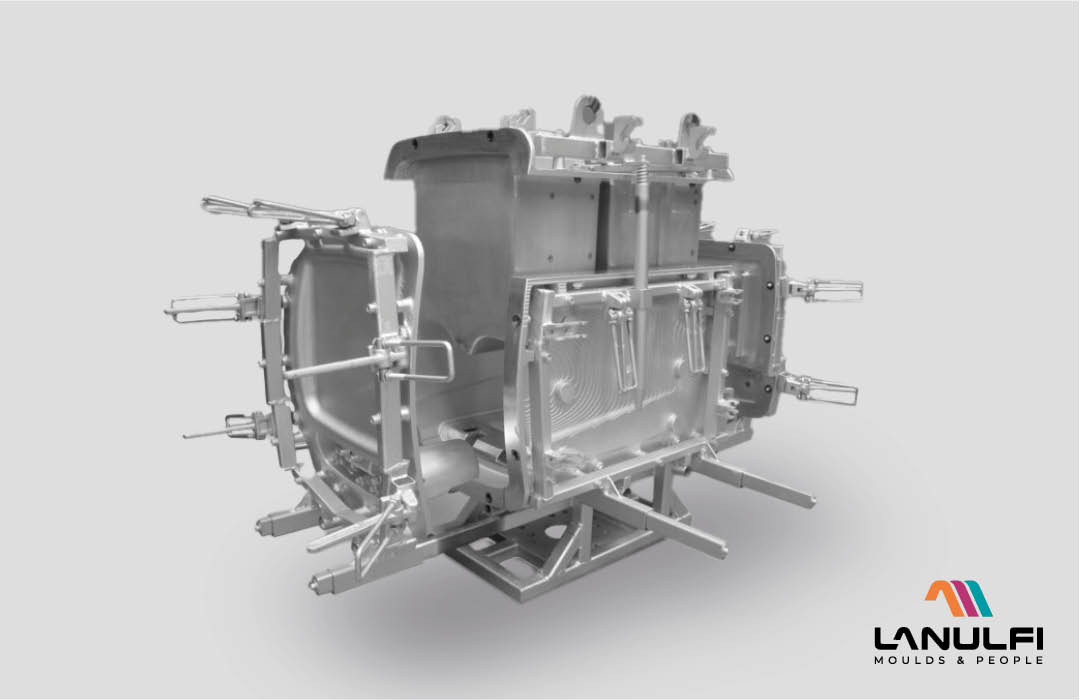

Moulds for Thermoplastics

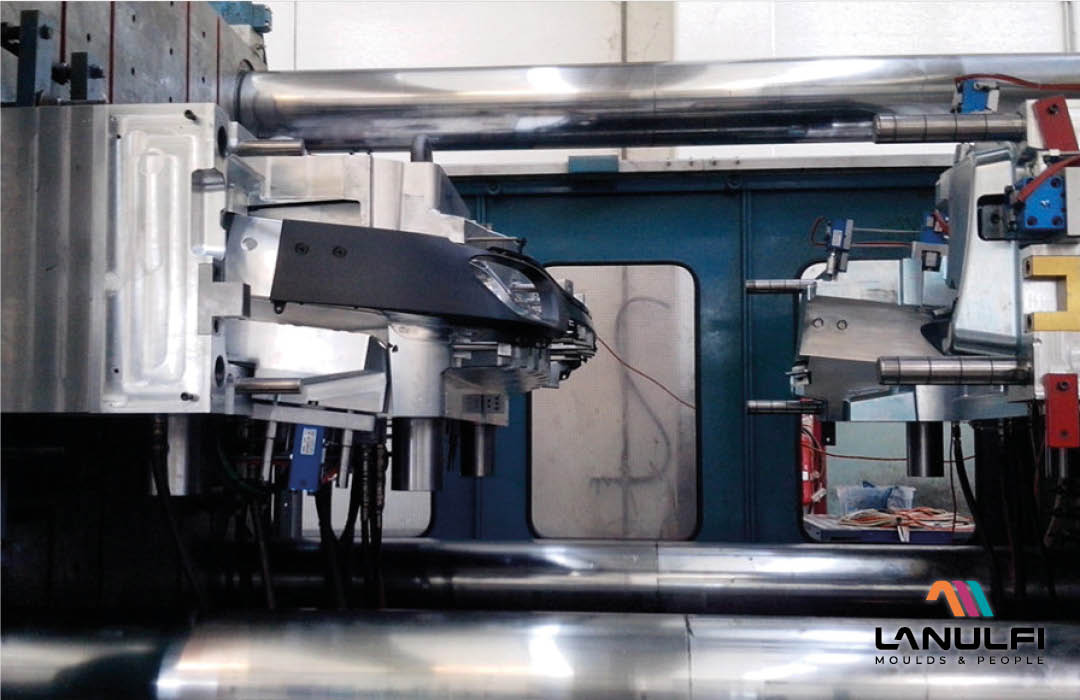

Thermoplastic injection moulds

In the injection mould industry, Lanulfi Company is able to provide its customers with very professional support that includes:

- co-design, and mould design

- structural and mouldflow analysis

- construction of prototype and series moulds

- sampling and small production runs

- dimensional testing

Examples of completed projects

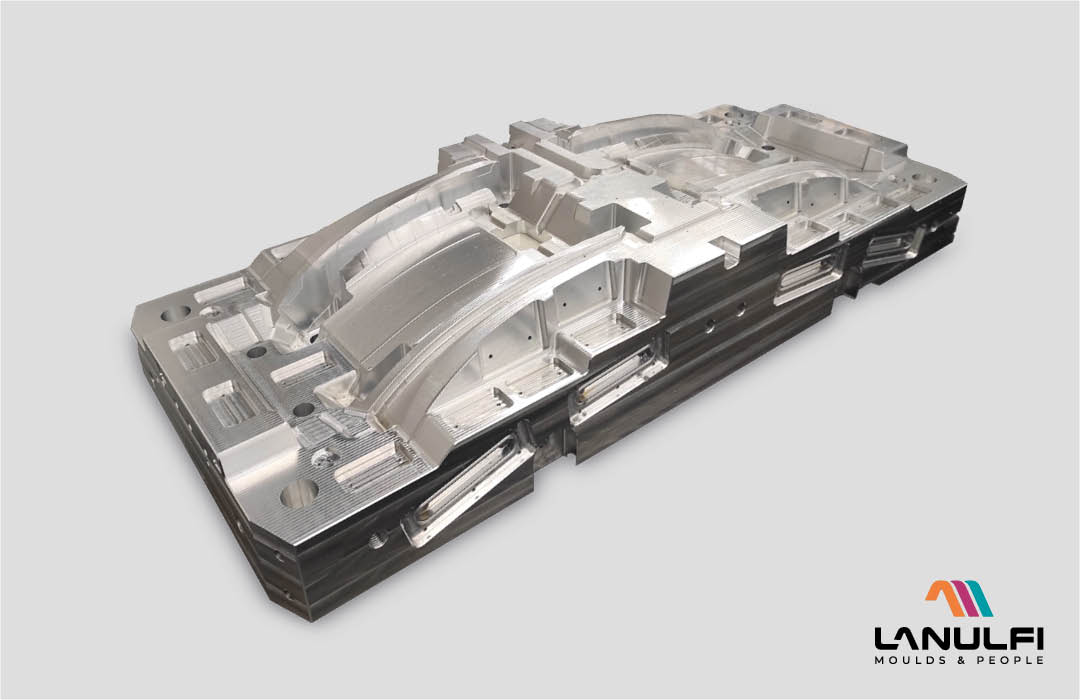

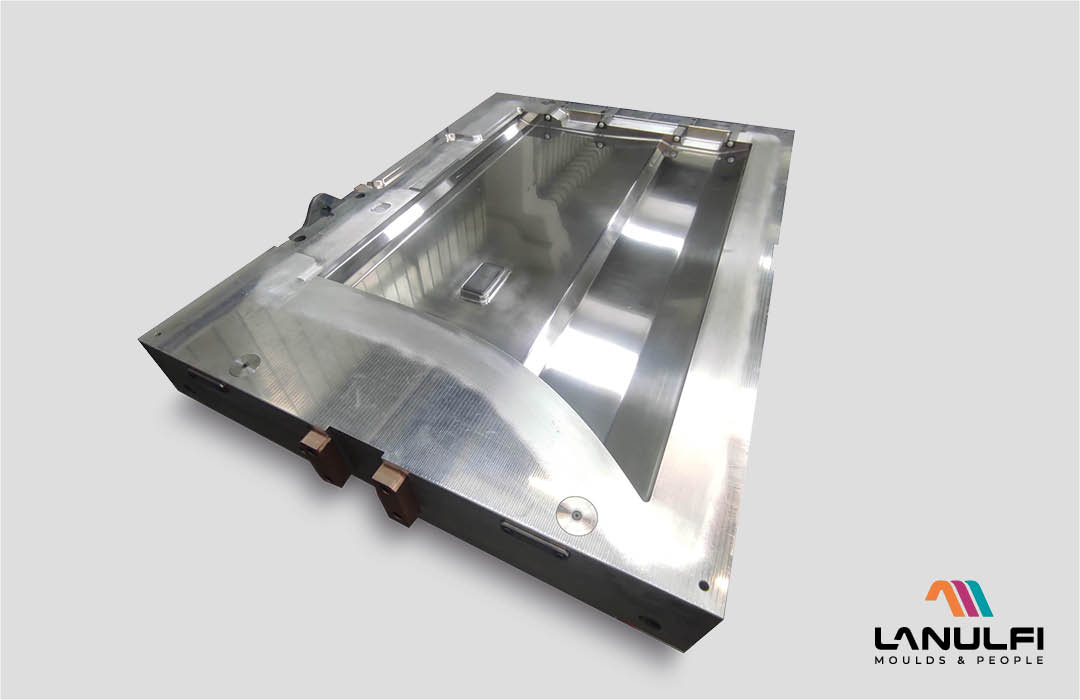

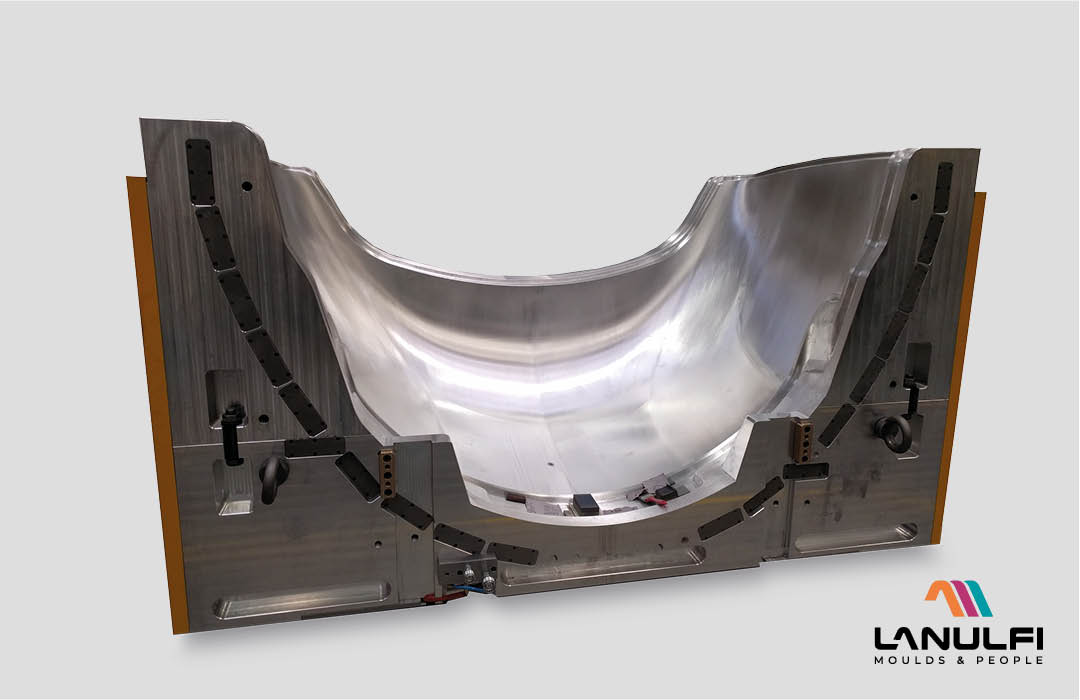

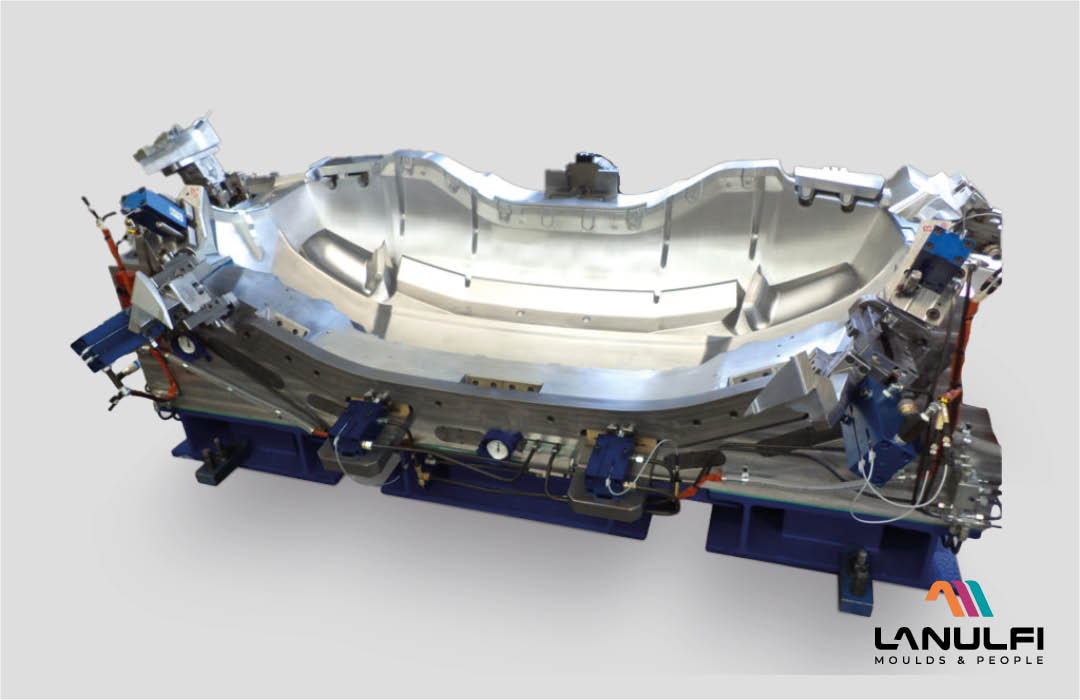

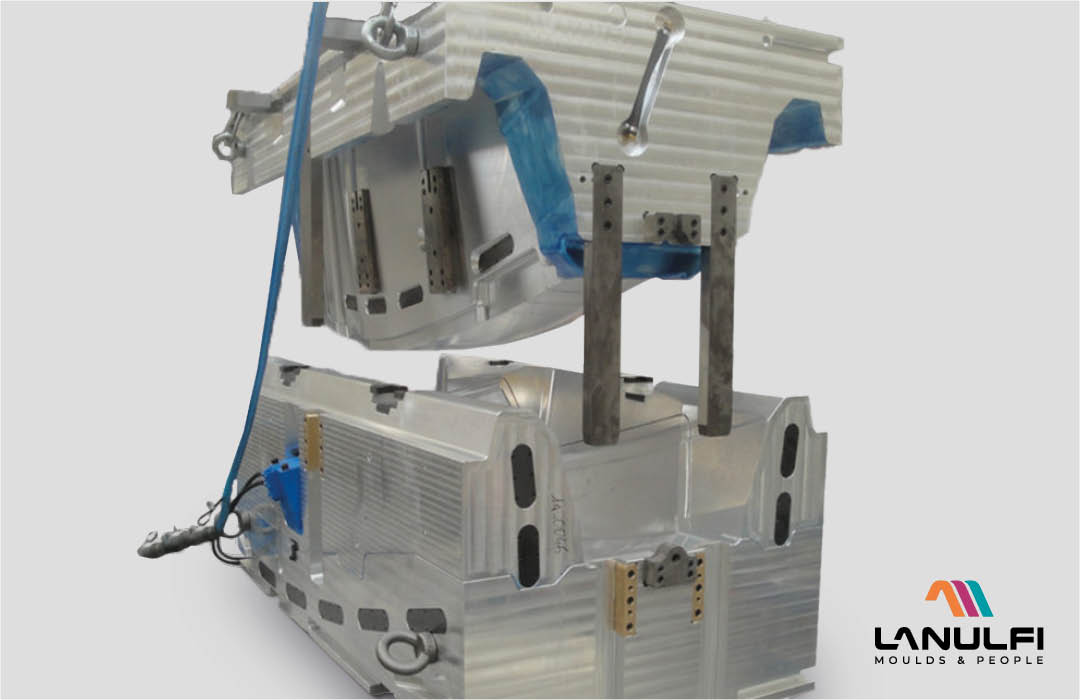

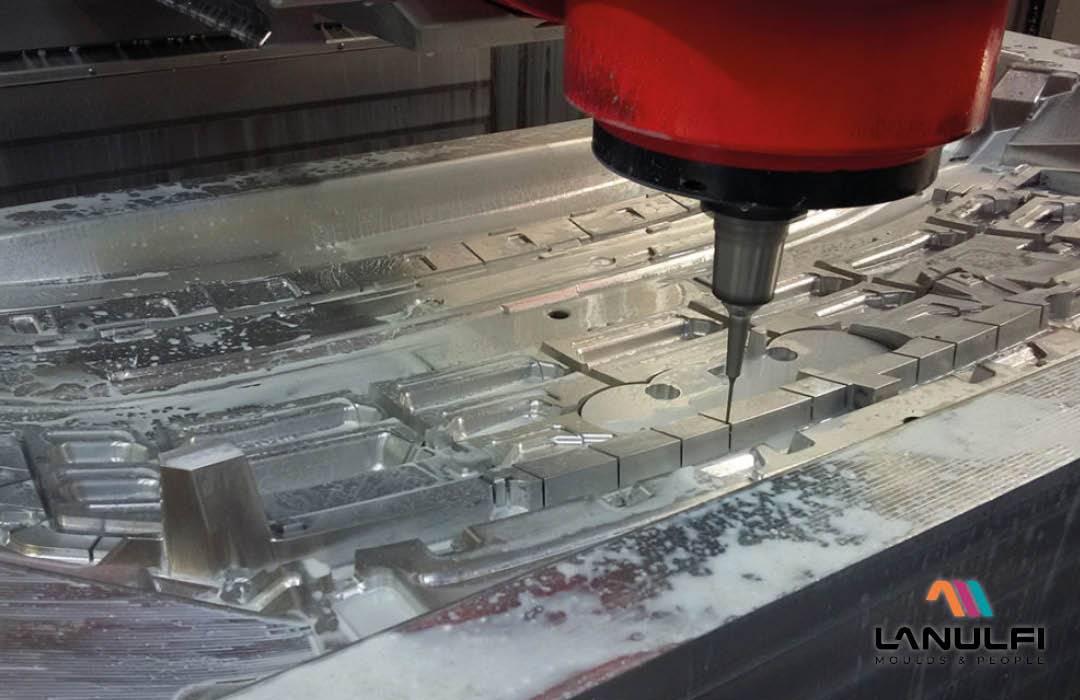

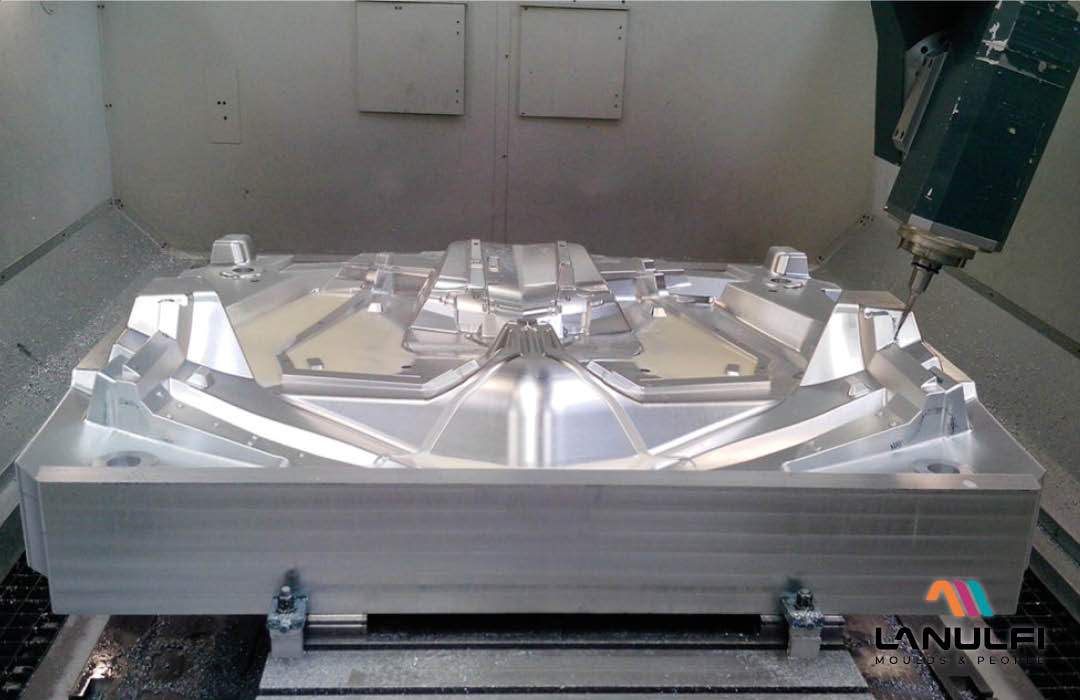

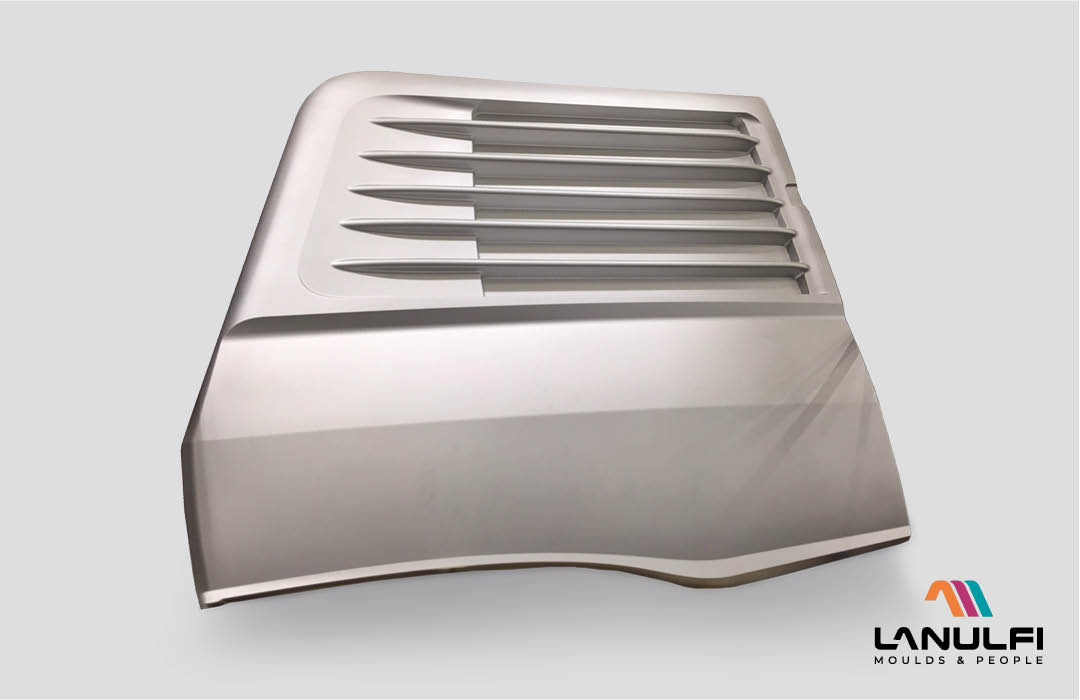

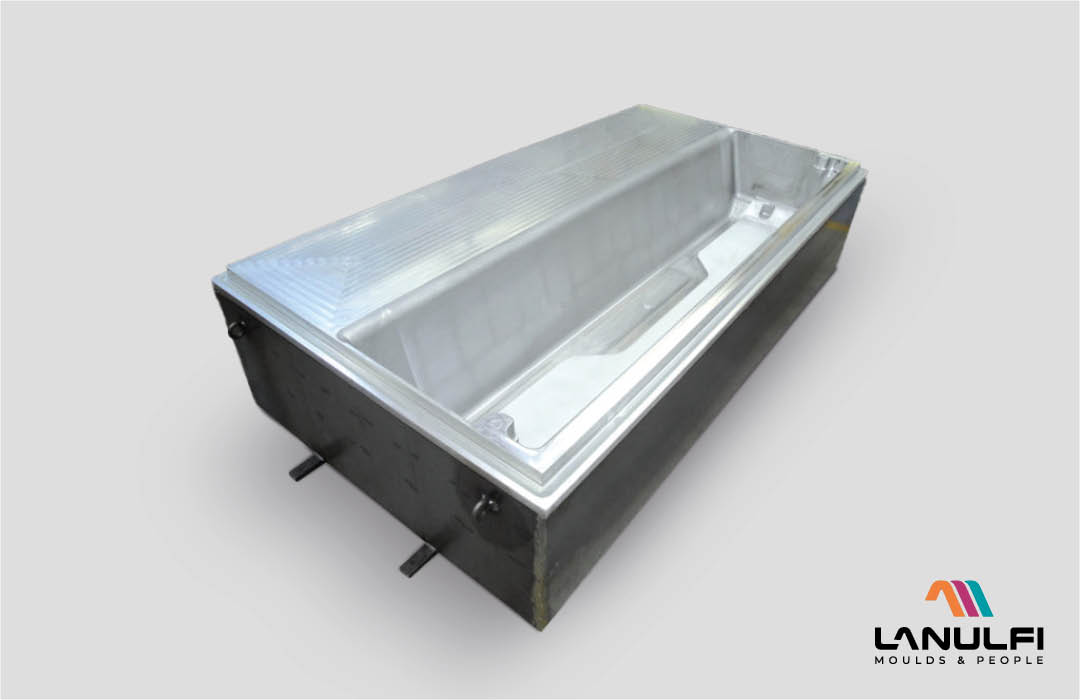

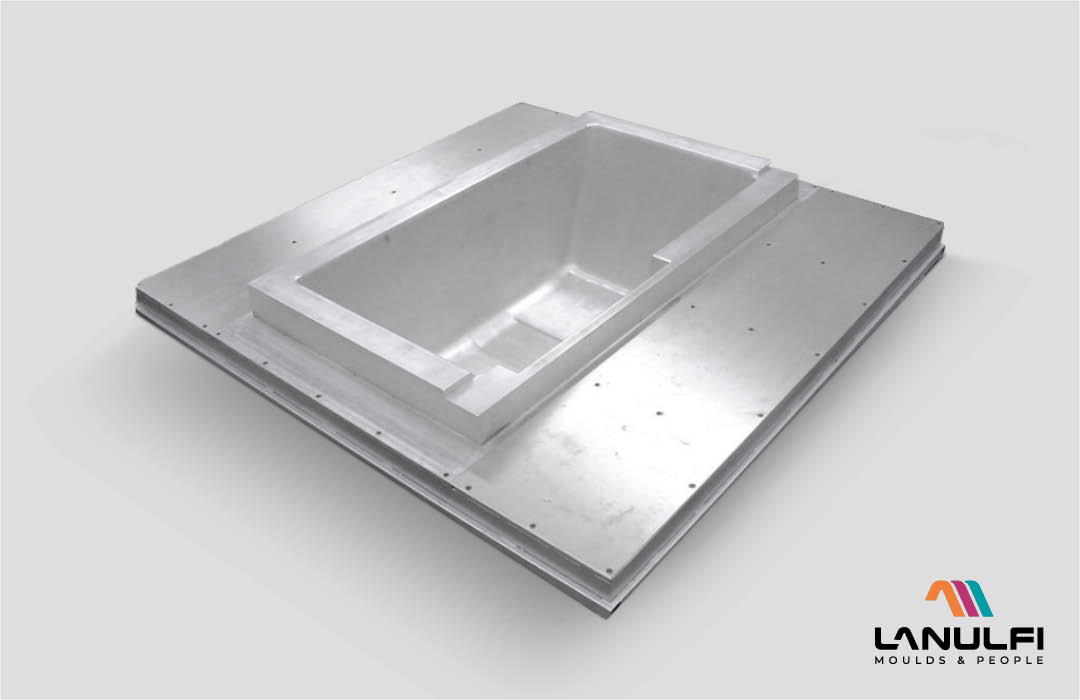

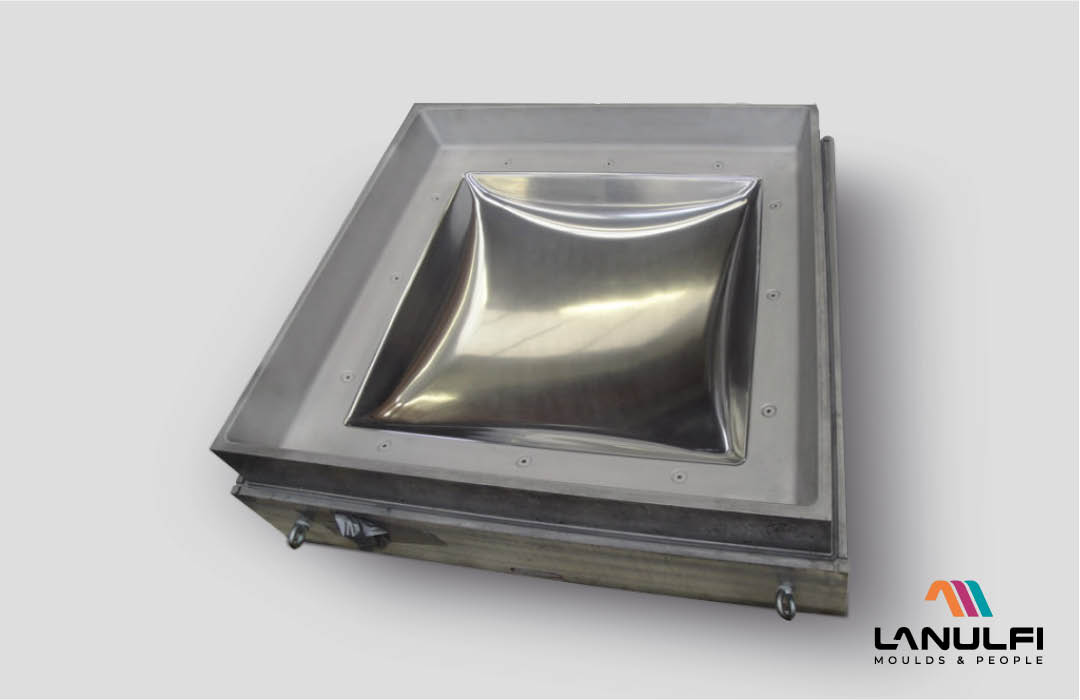

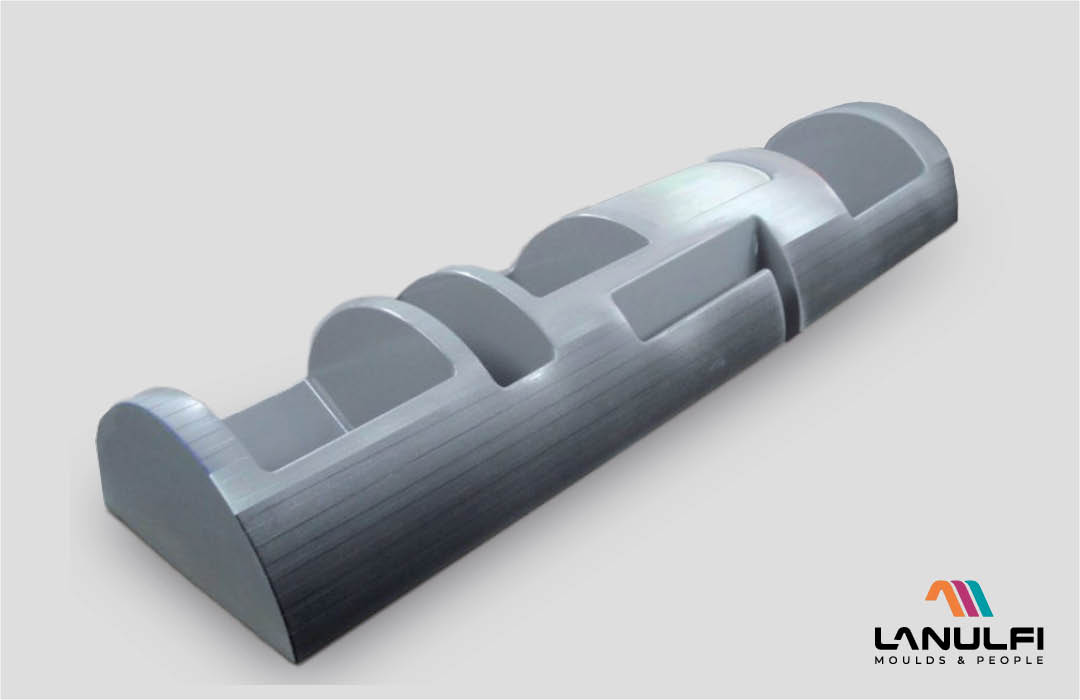

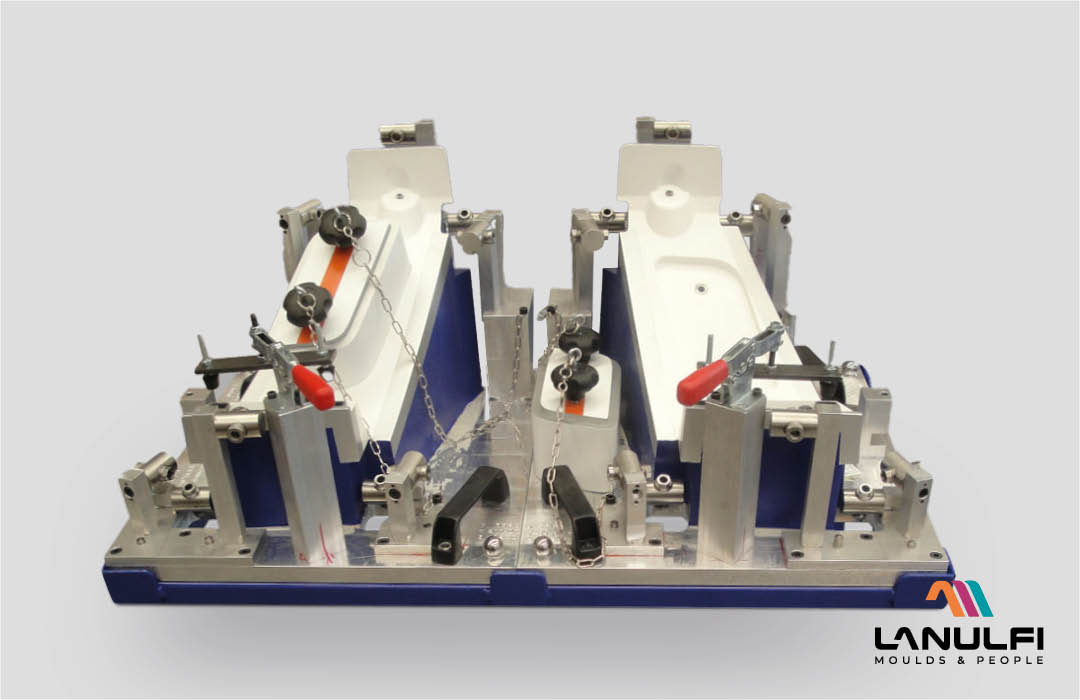

Thermoforming Moulds

Vacuum and twin-sheet thermoforming moulds

Our moulding experience enables us to make thermoforming moulds using both current CNC milling techniques and traditional methods; equipment made of cast or sheet aluminum, resin or wood.

Thermoforming moulds from sheet:

- vacuum

- compressive

- twin-sheet

Examples of completed projects

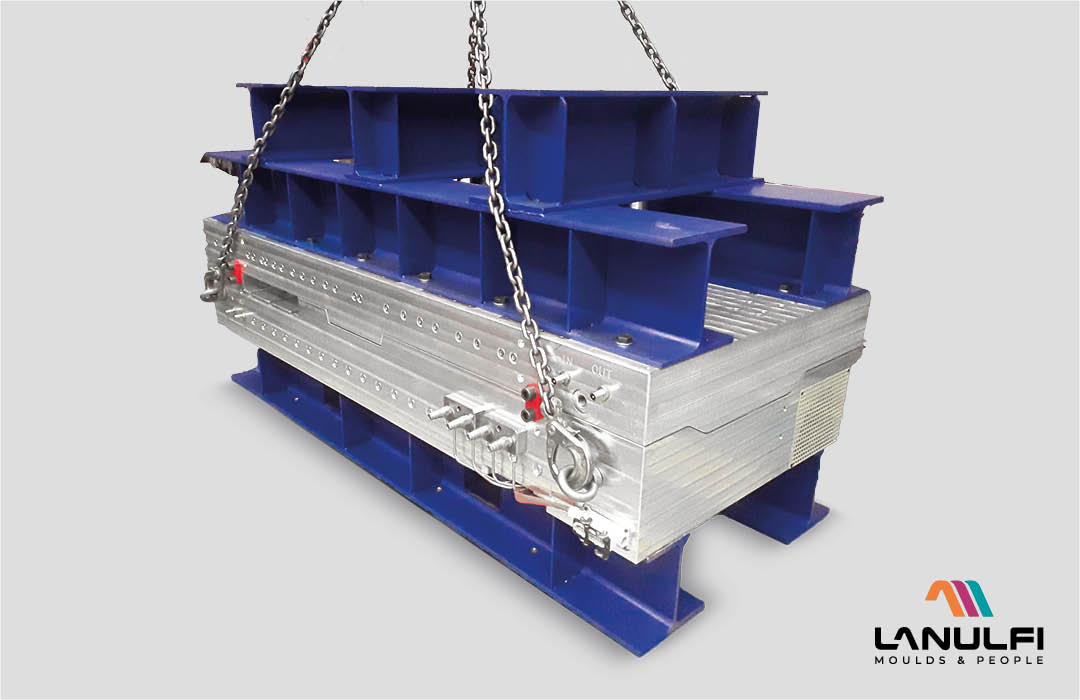

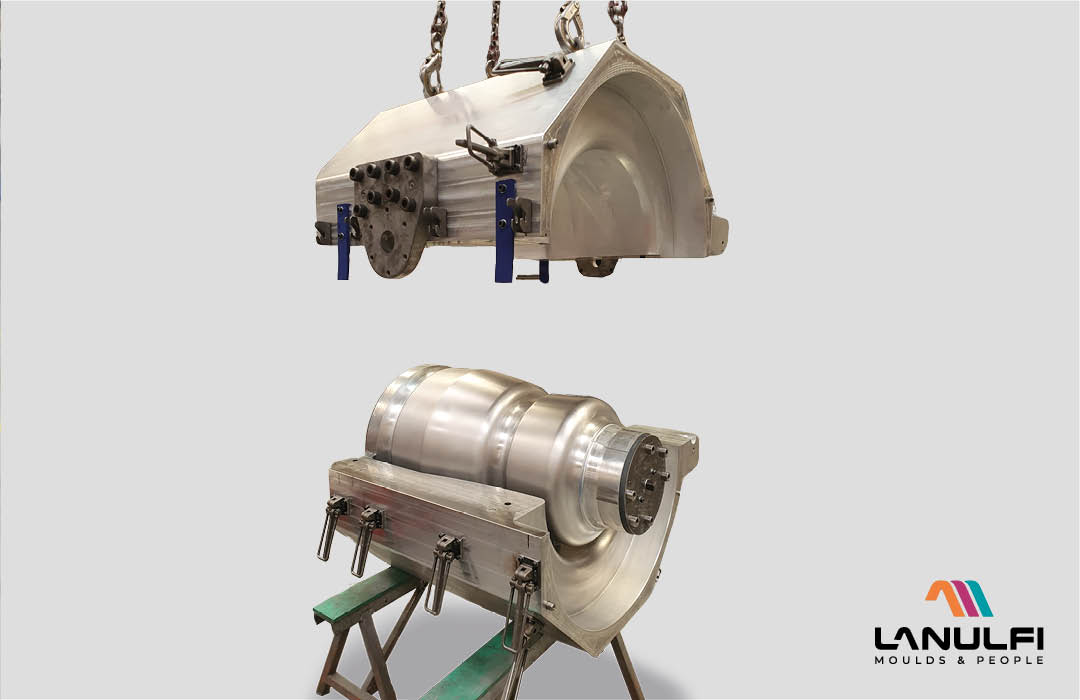

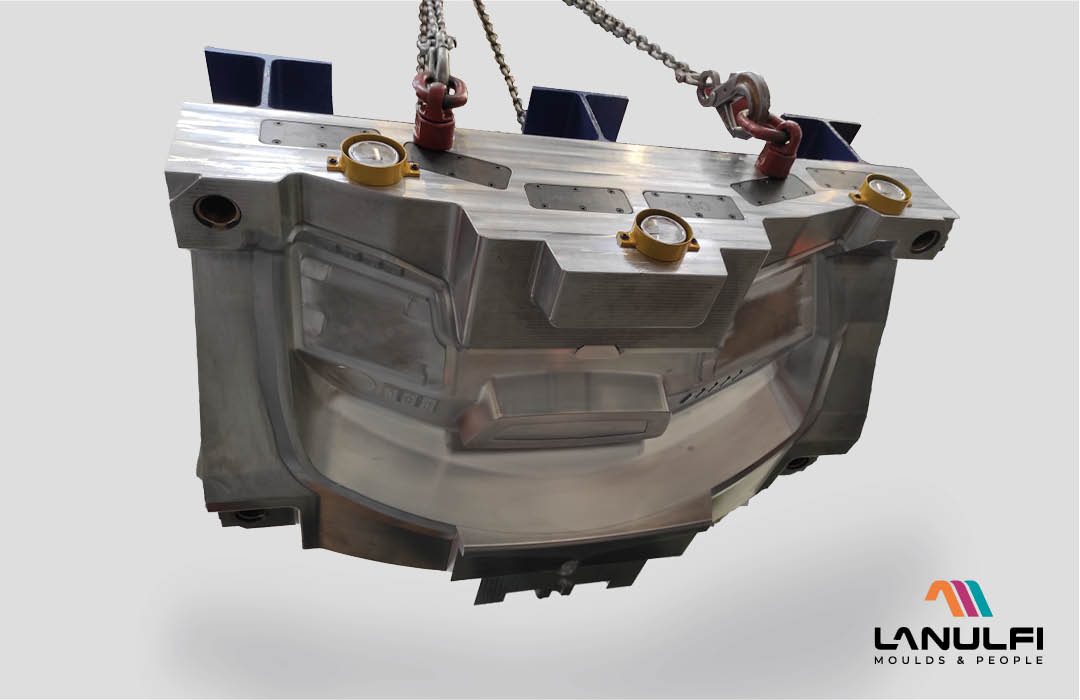

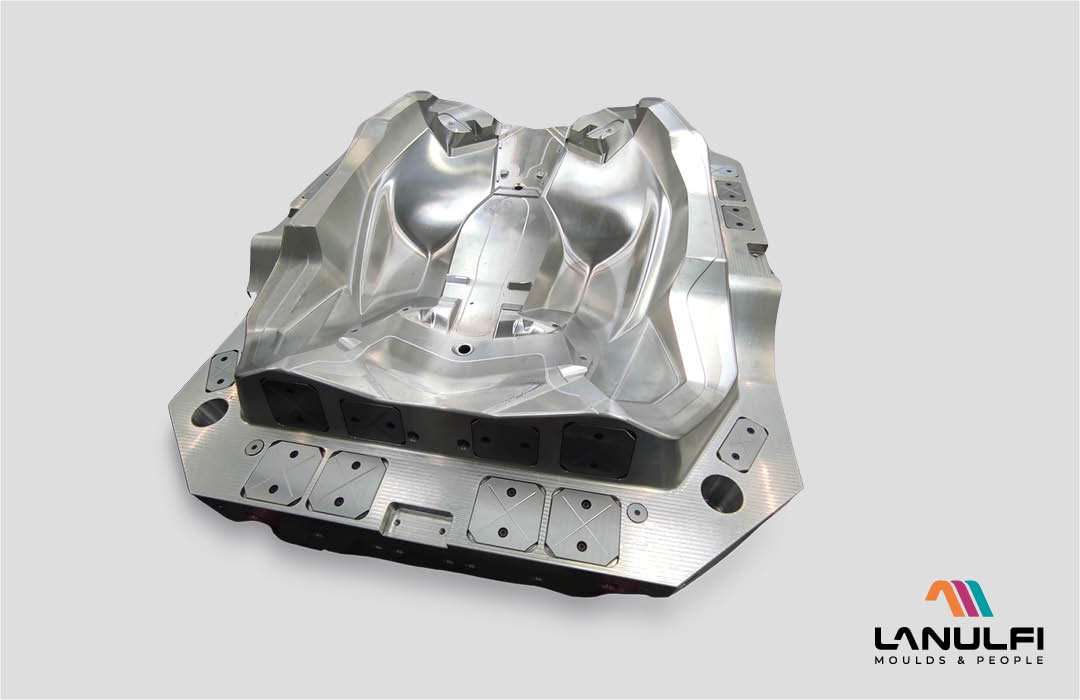

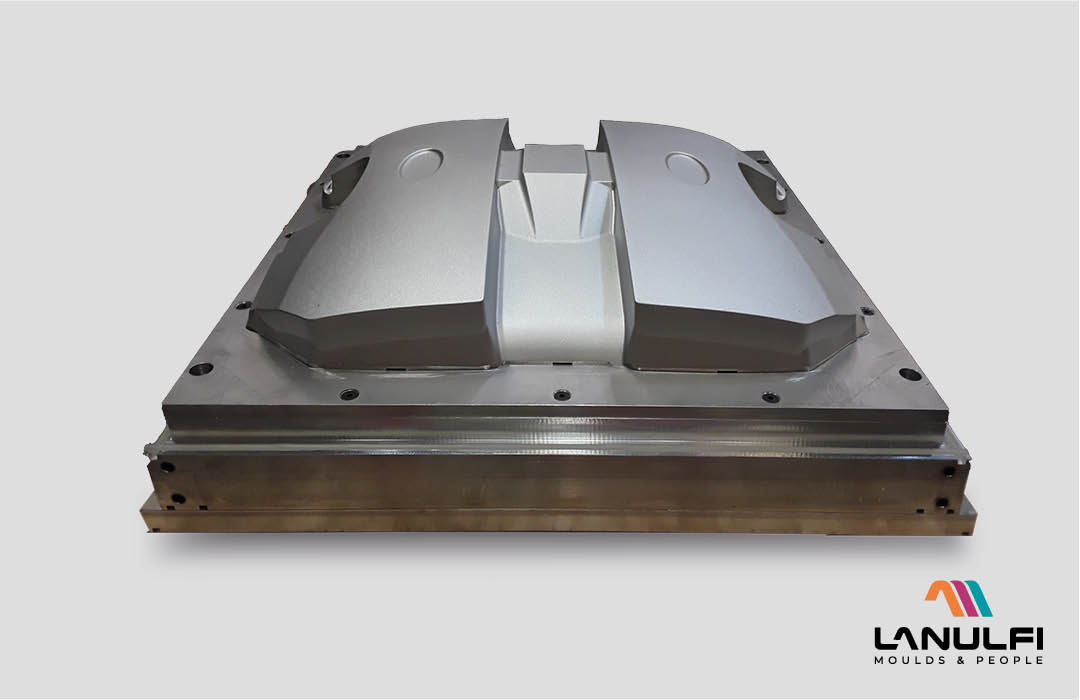

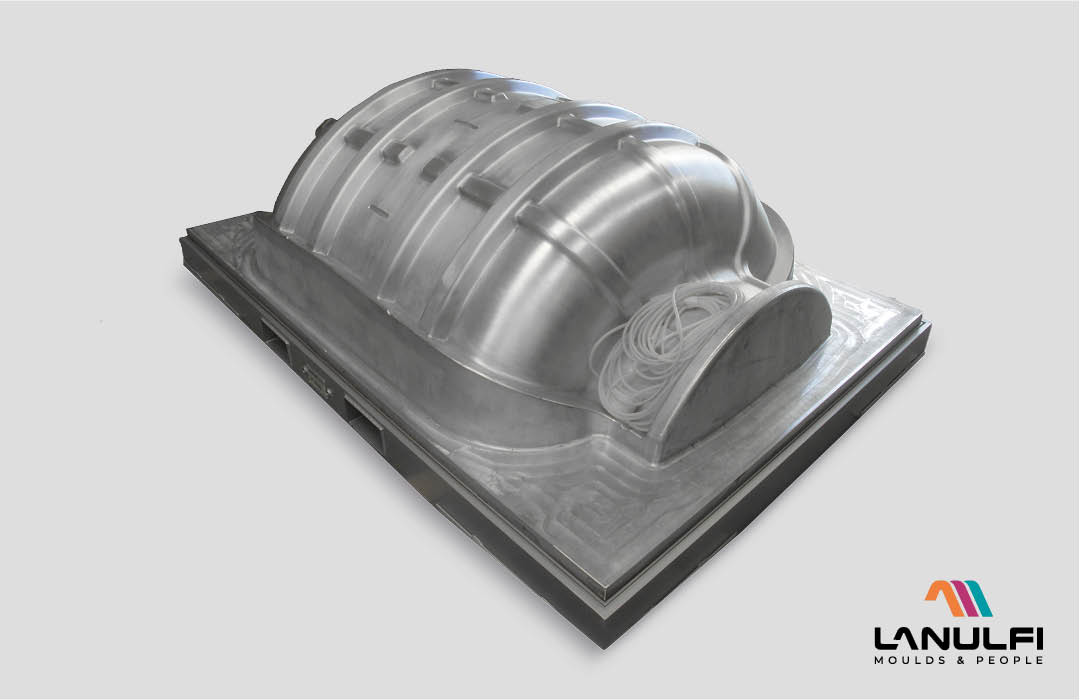

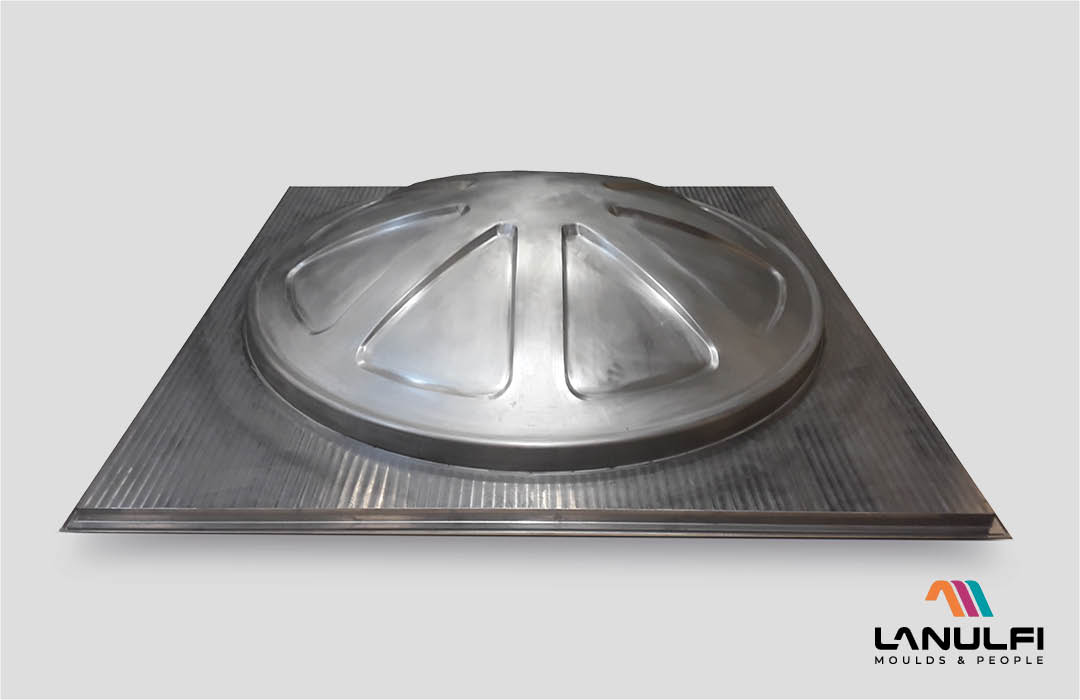

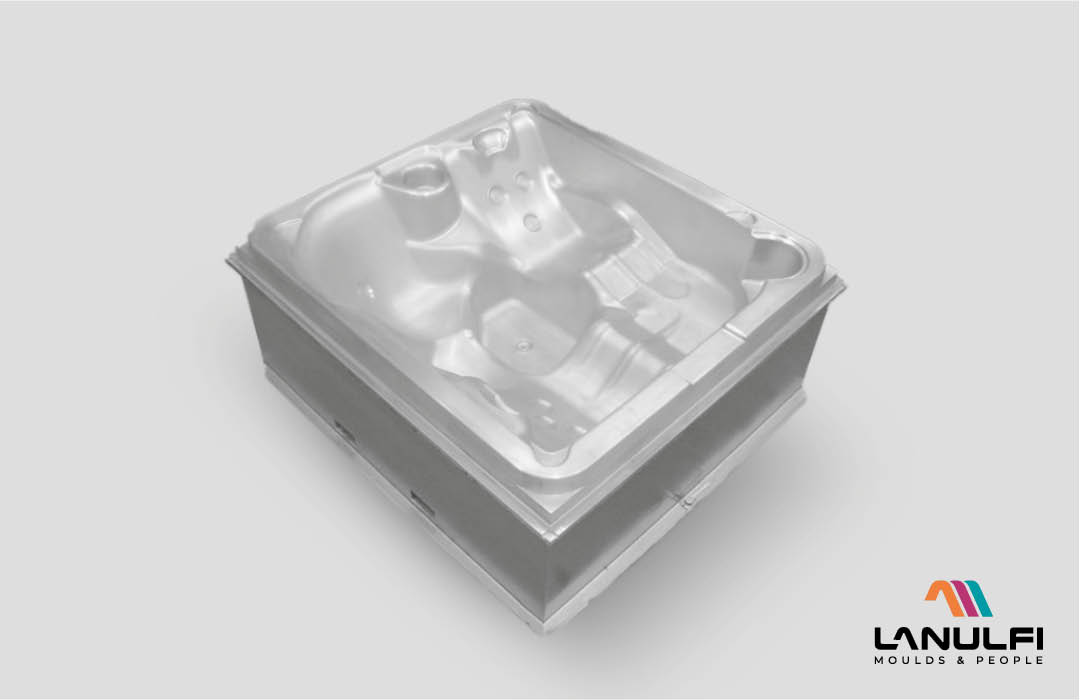

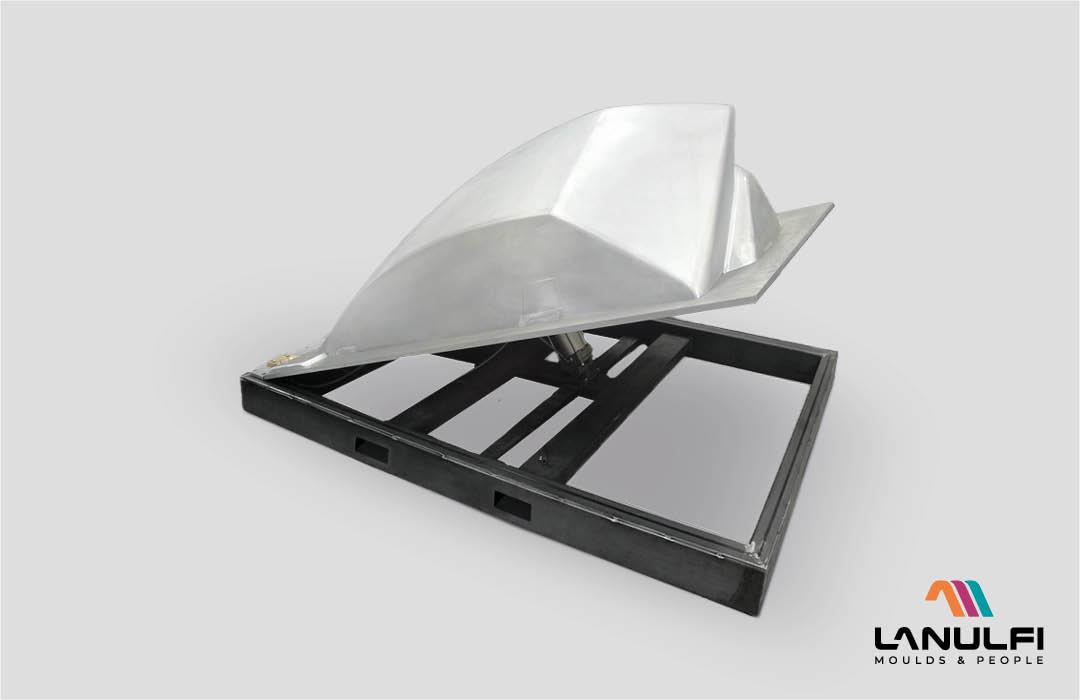

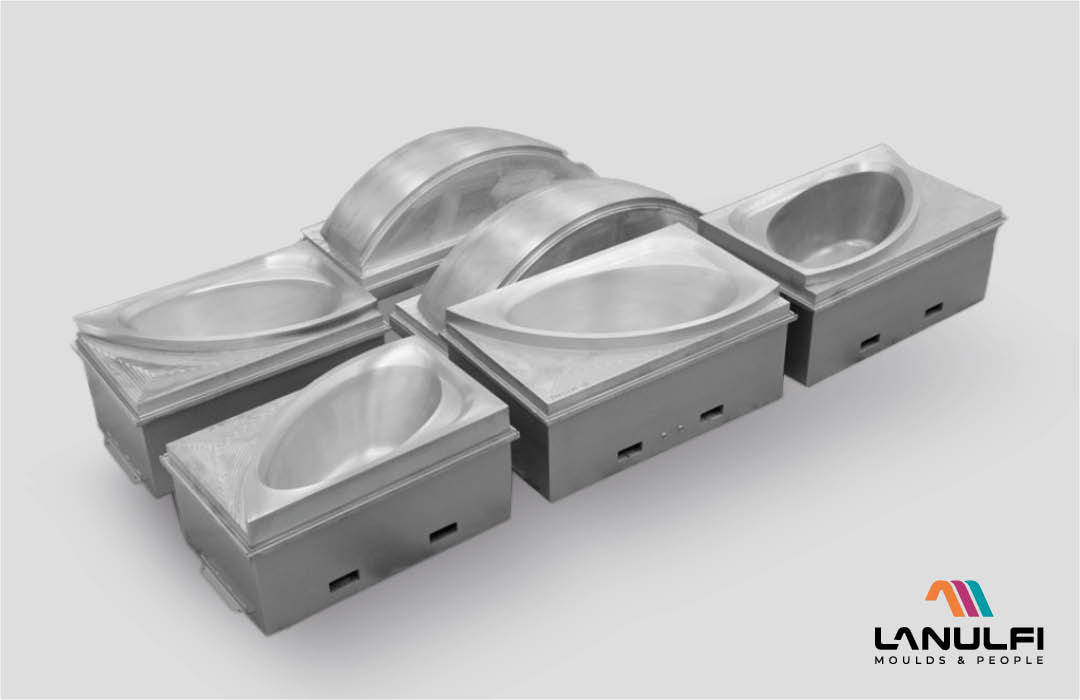

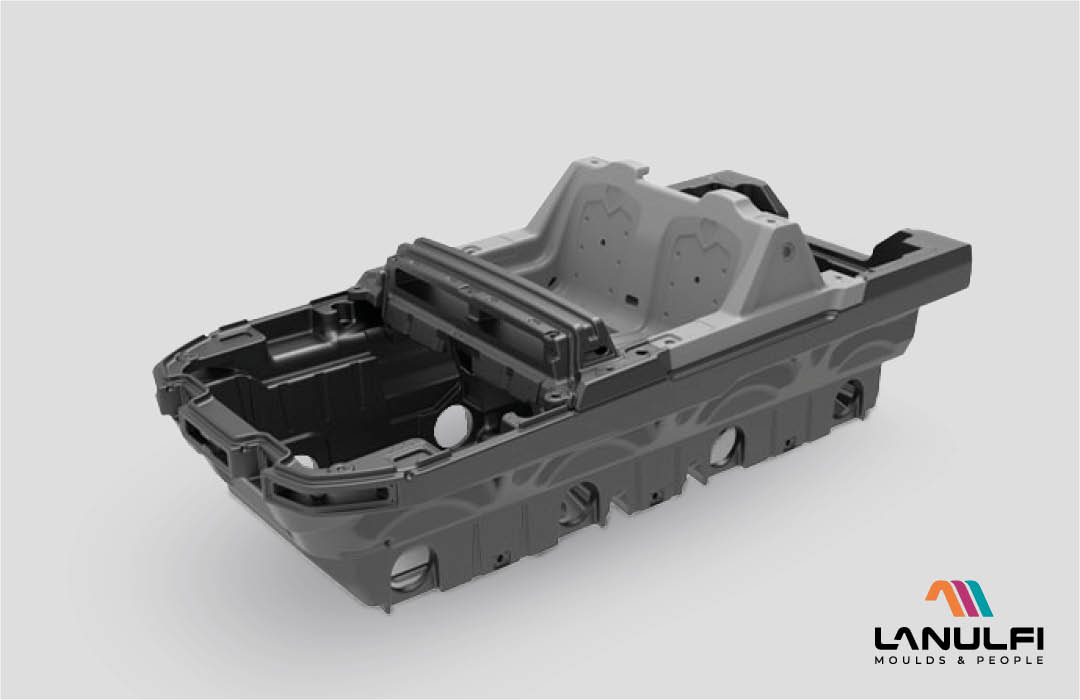

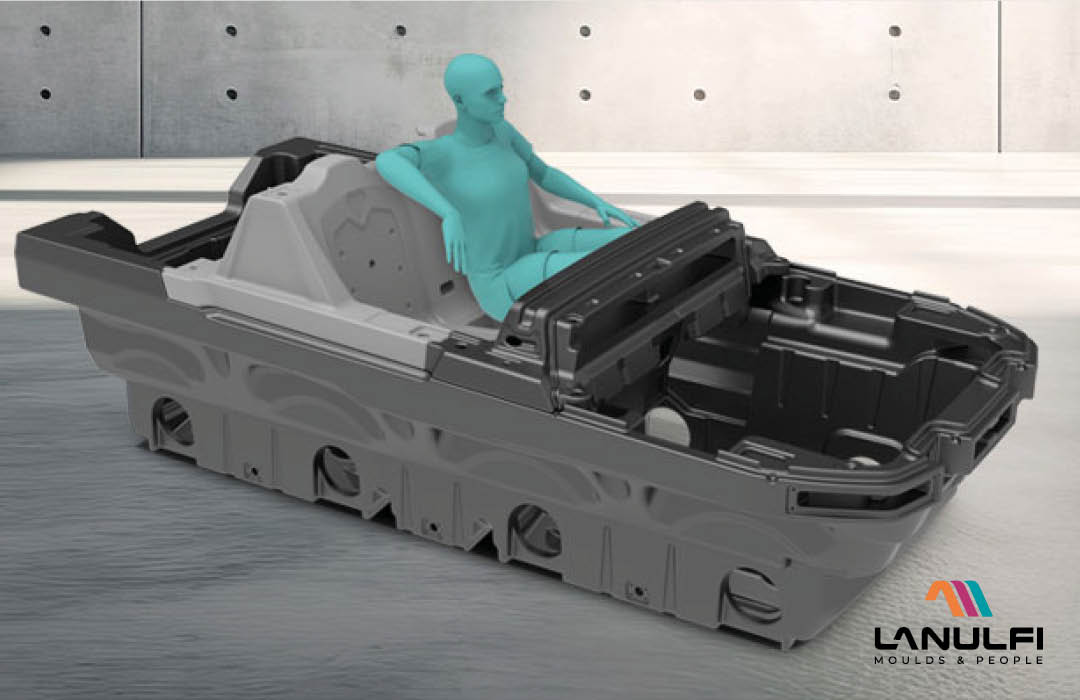

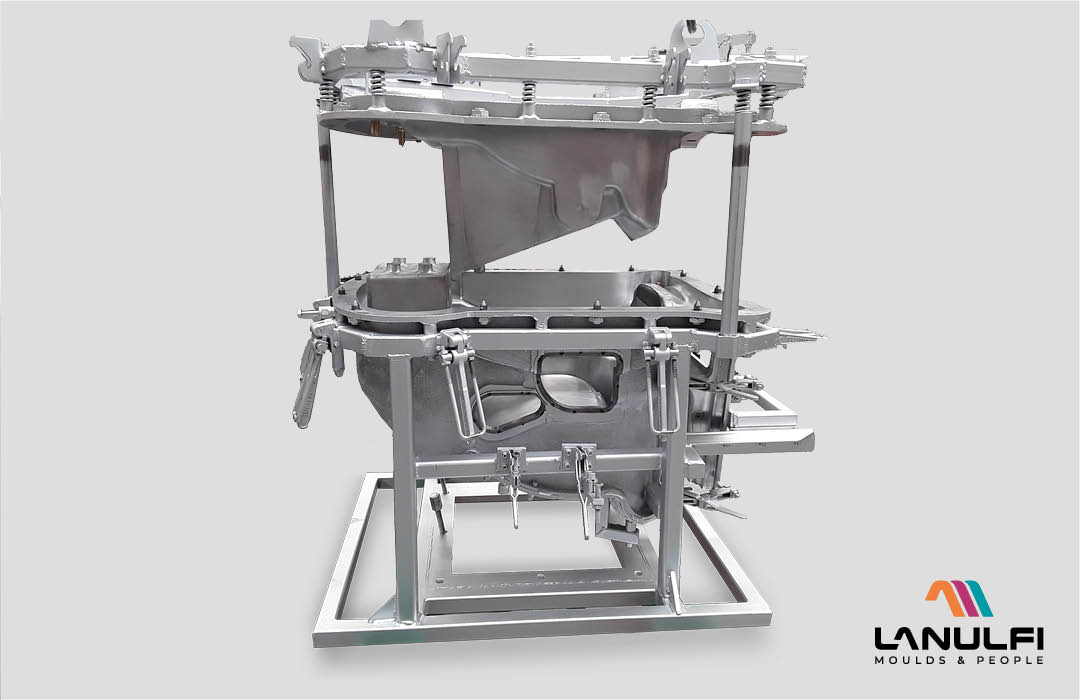

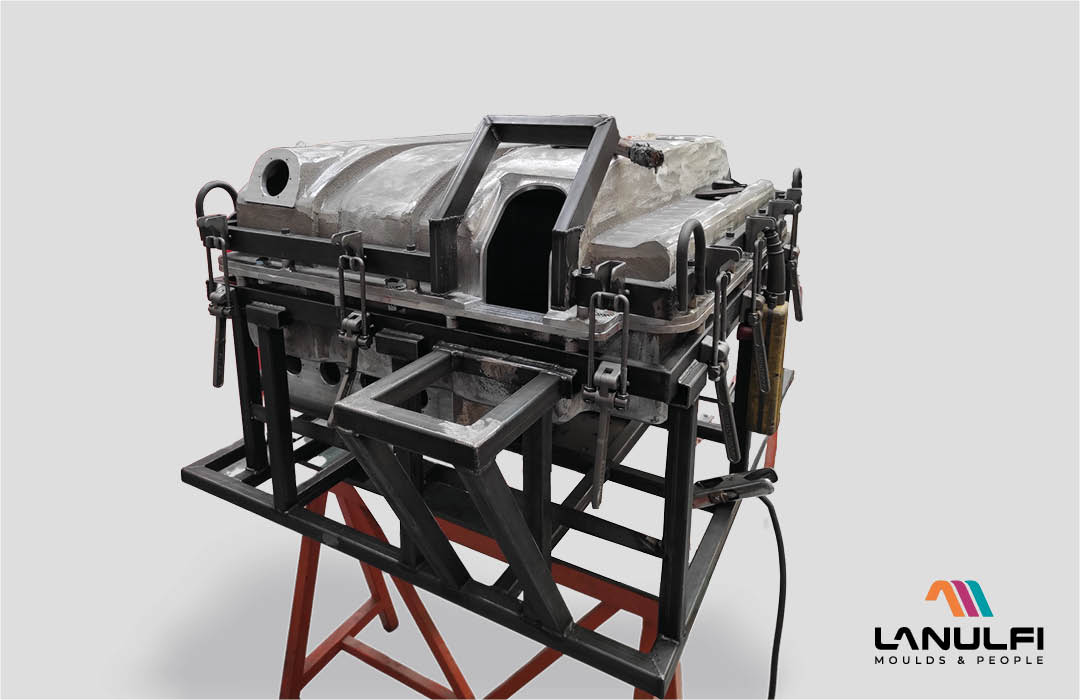

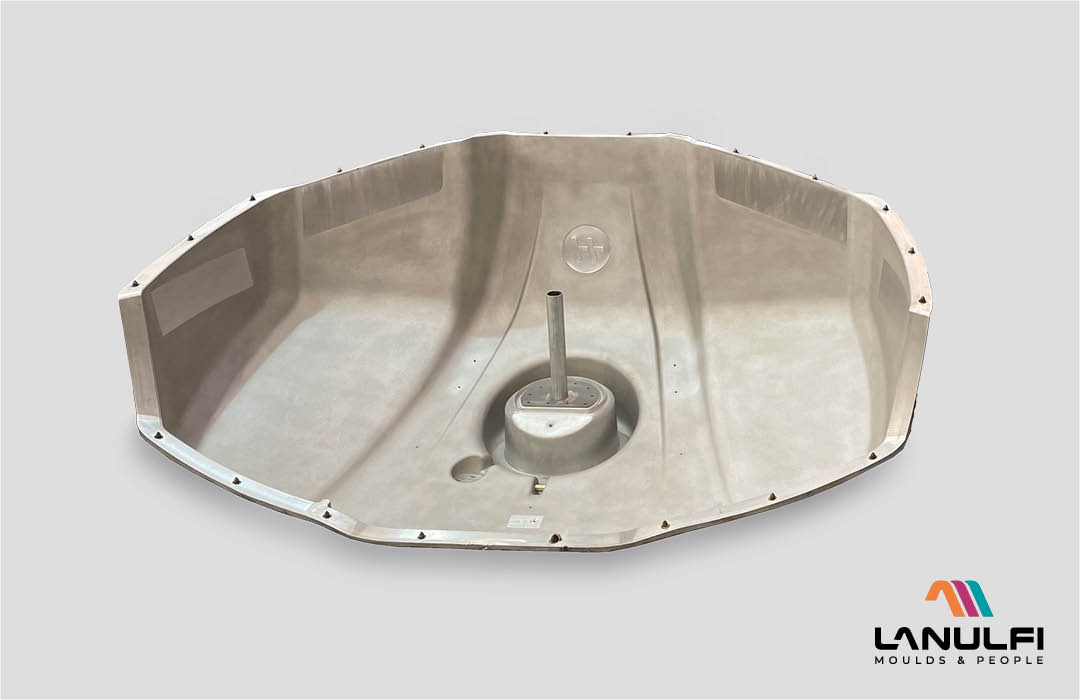

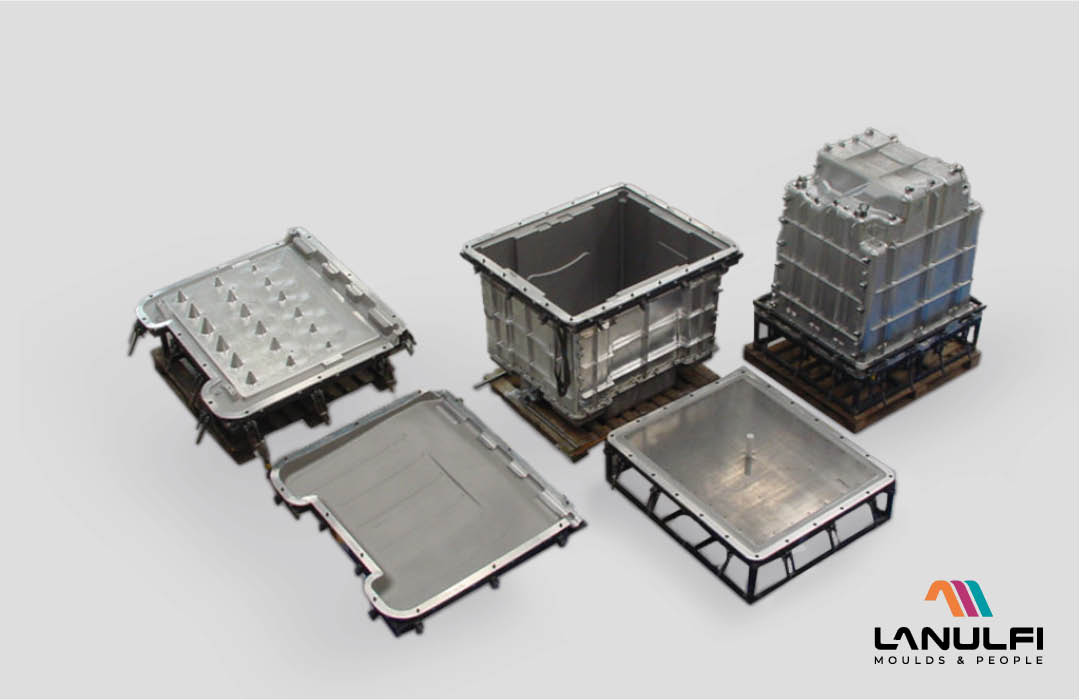

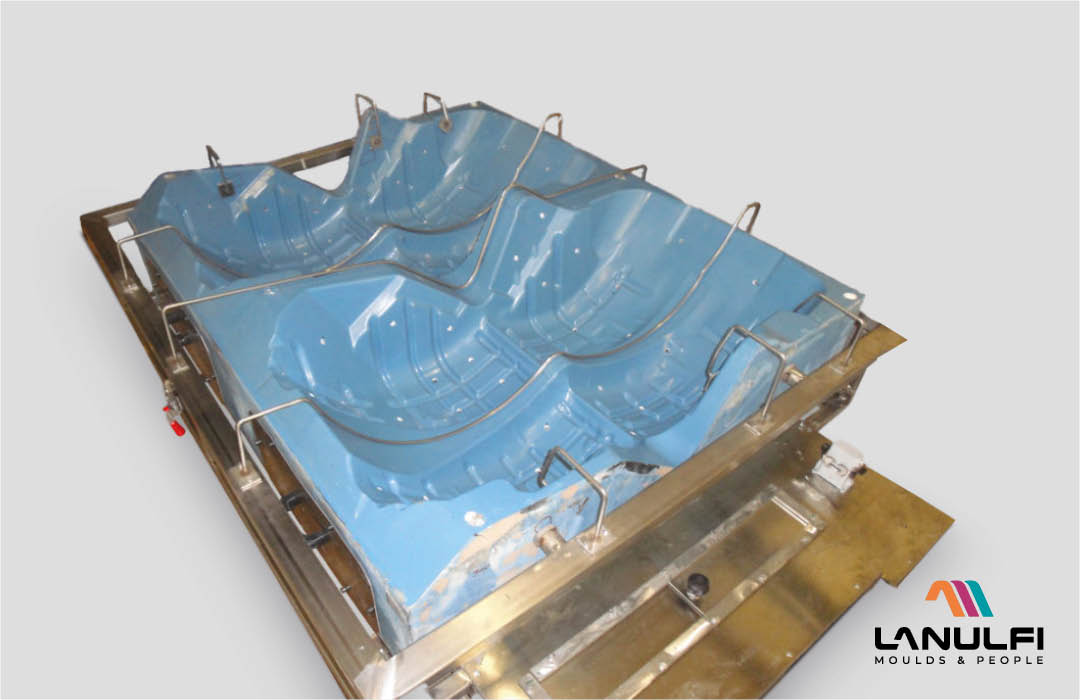

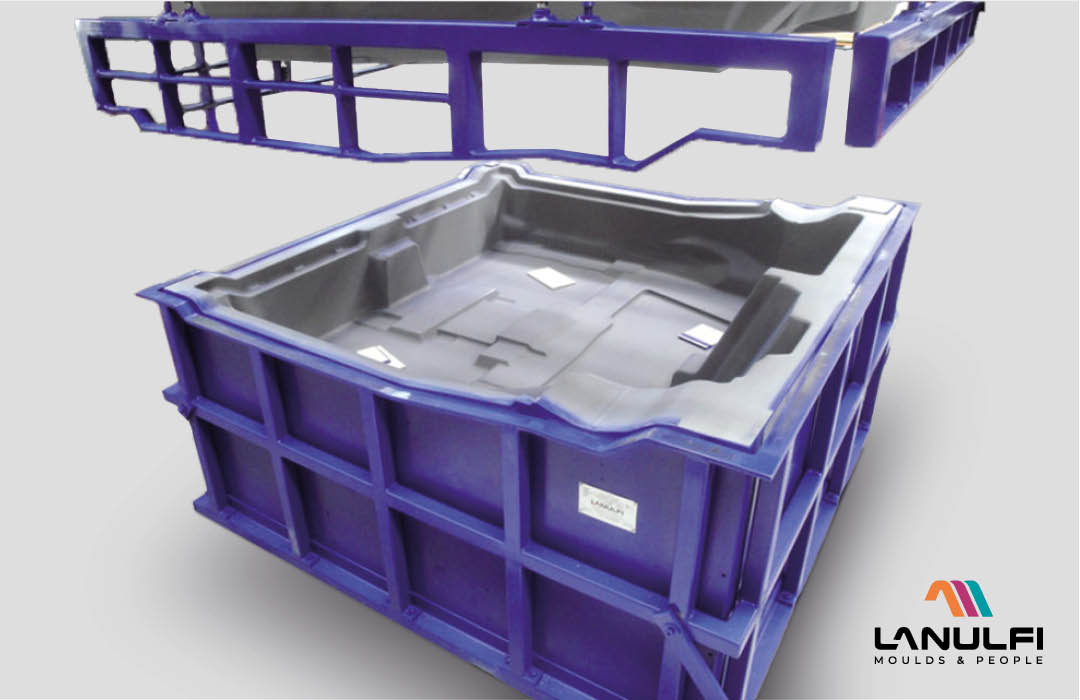

Moulds for Rotational

Planners and designers are increasingly appreciating the possibility of making complex and aesthetic shapes through the use of rotomoulding technology, and Lanulfi is able to make rotomoulding moulds with increasingly complicated geometries that can produce multifunctional industrial parts and beautiful furniture and design objects

TYPES AND SECTORS

- Design products: chairs, tables, lamps and design objects, etc.

- Industrial products: tanks, load-bearing shells, etc.

- Medical: hospital furniture

- Agromechanical: tanks, roofs of agricultural machinery, etc.

Examples of completed projects

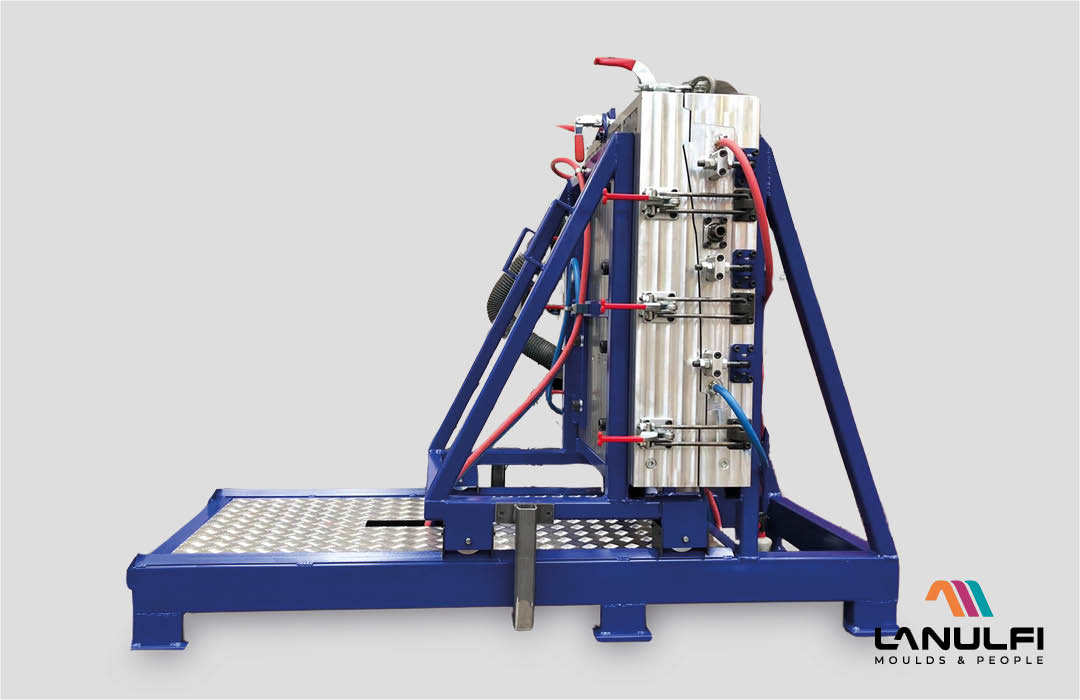

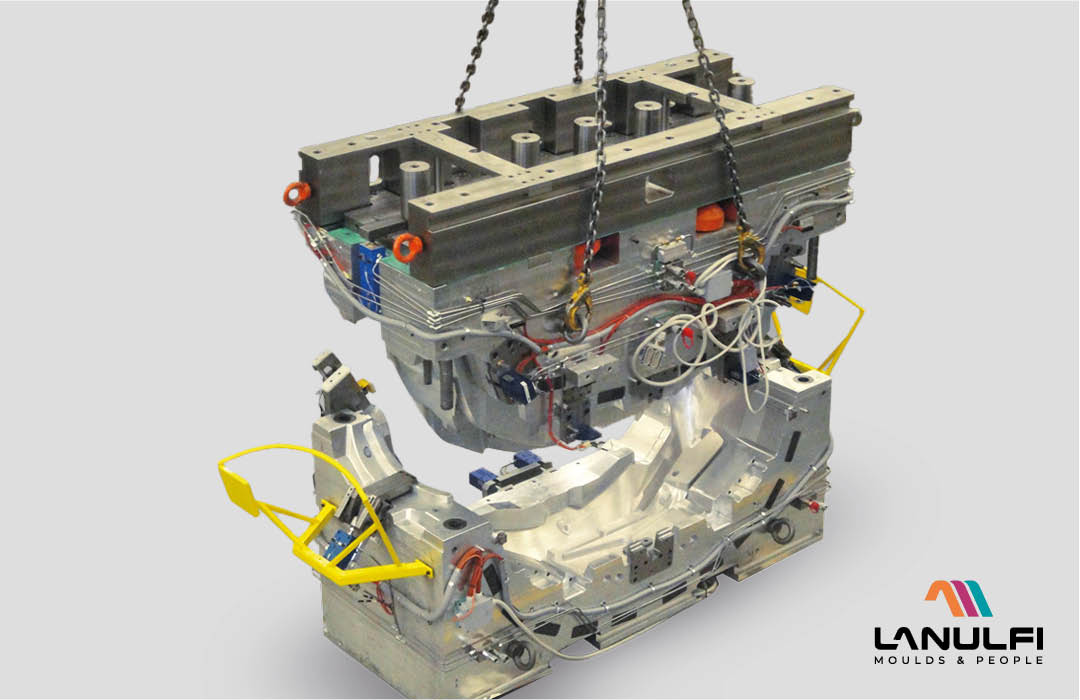

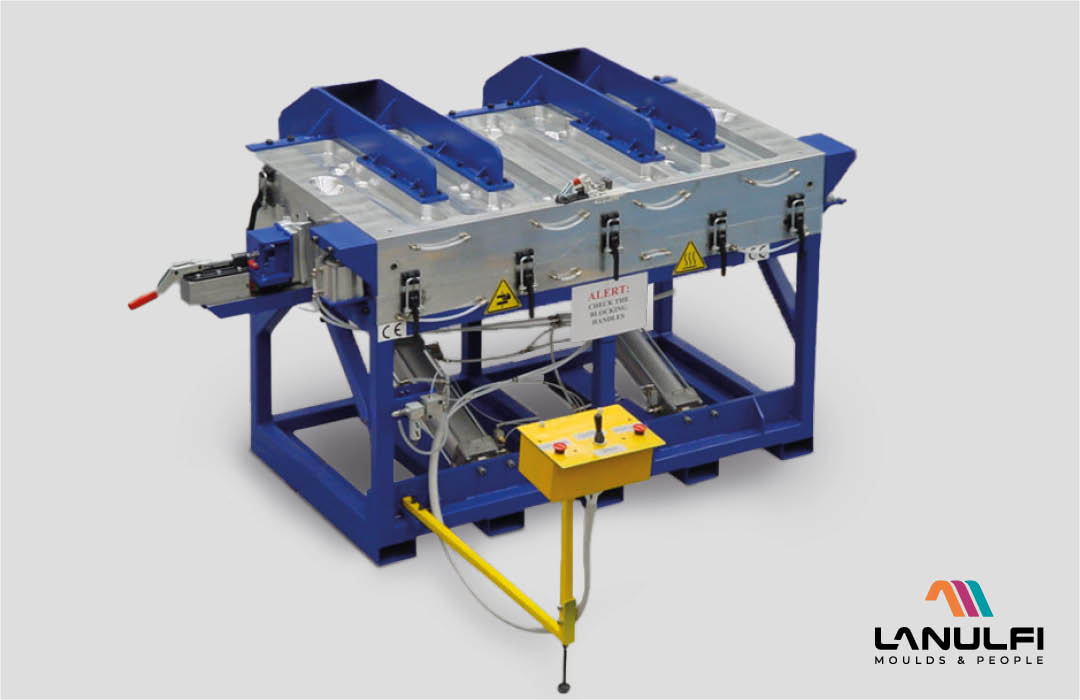

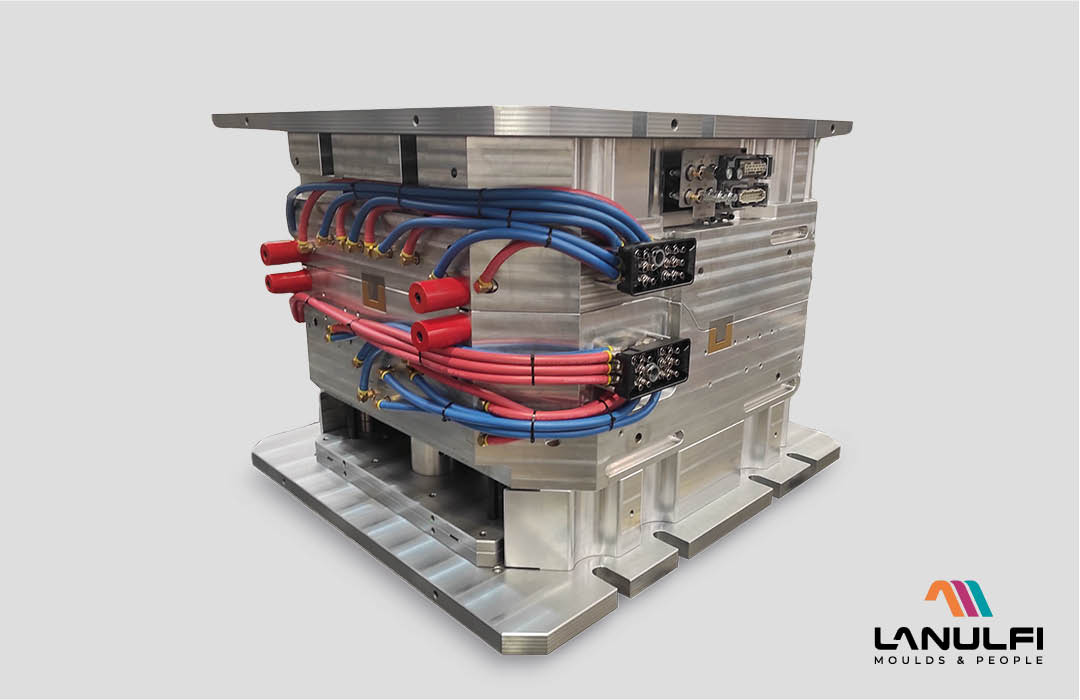

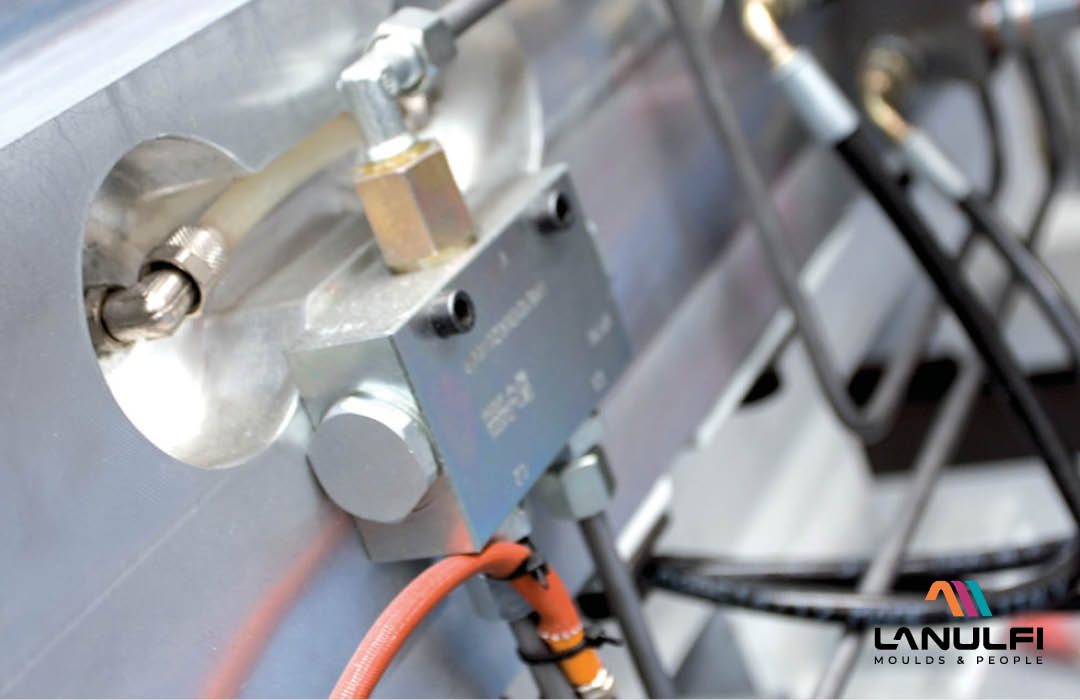

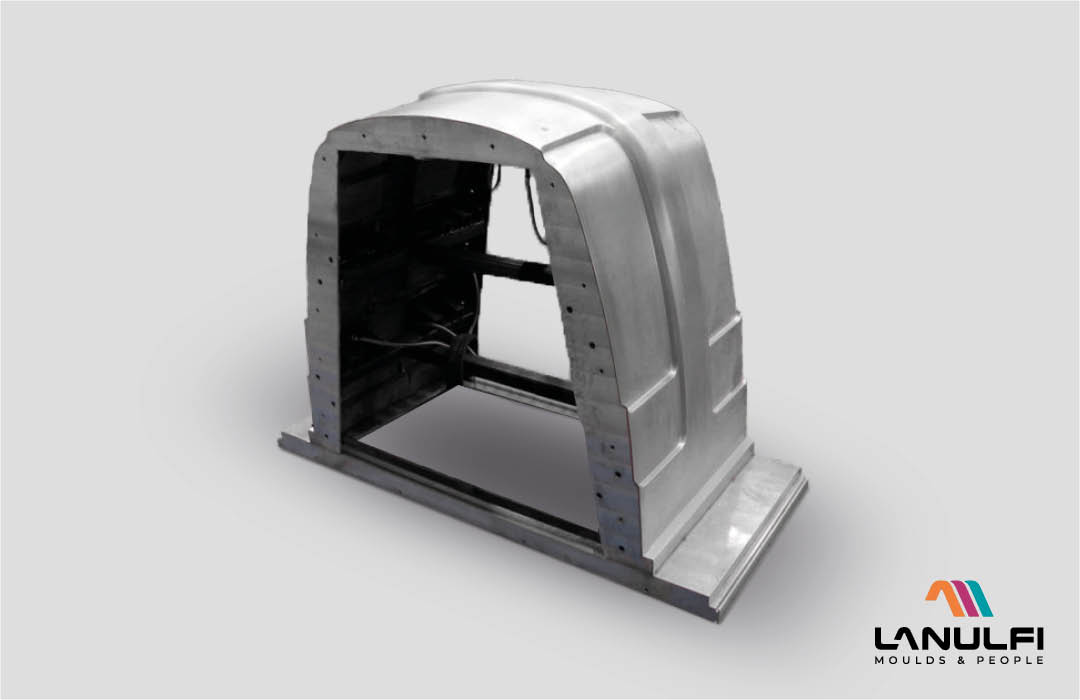

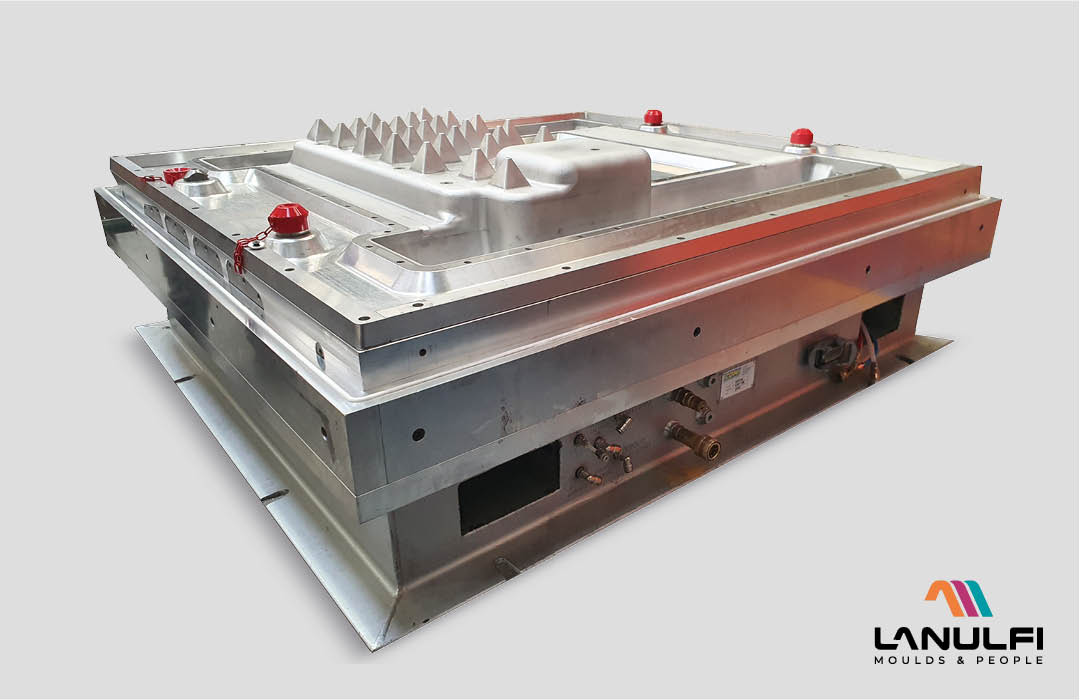

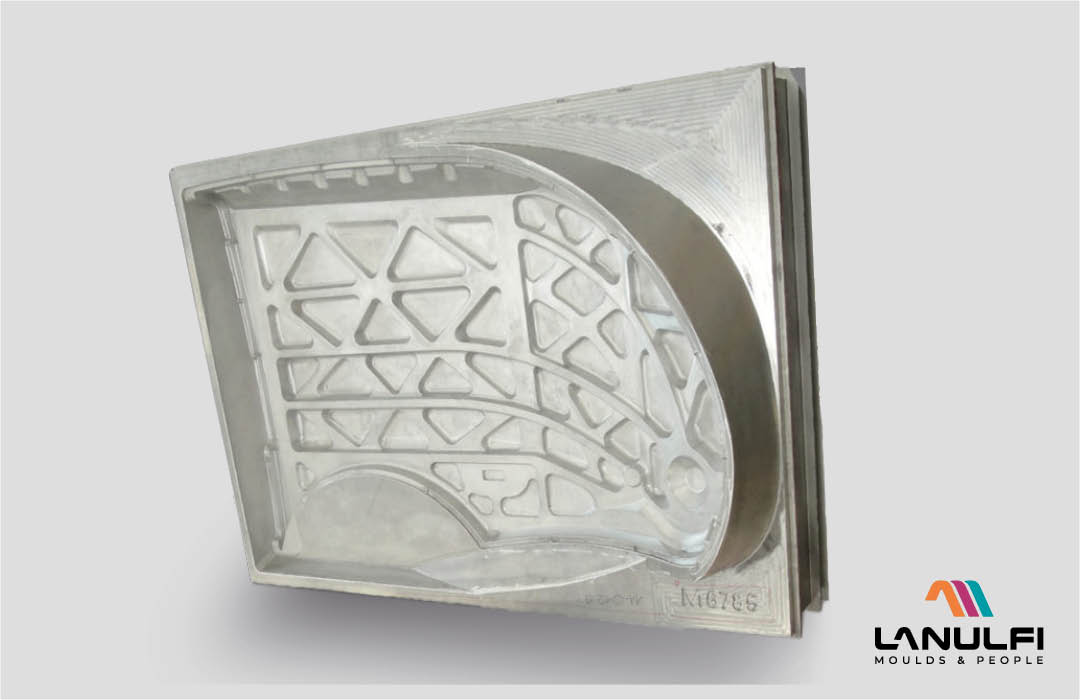

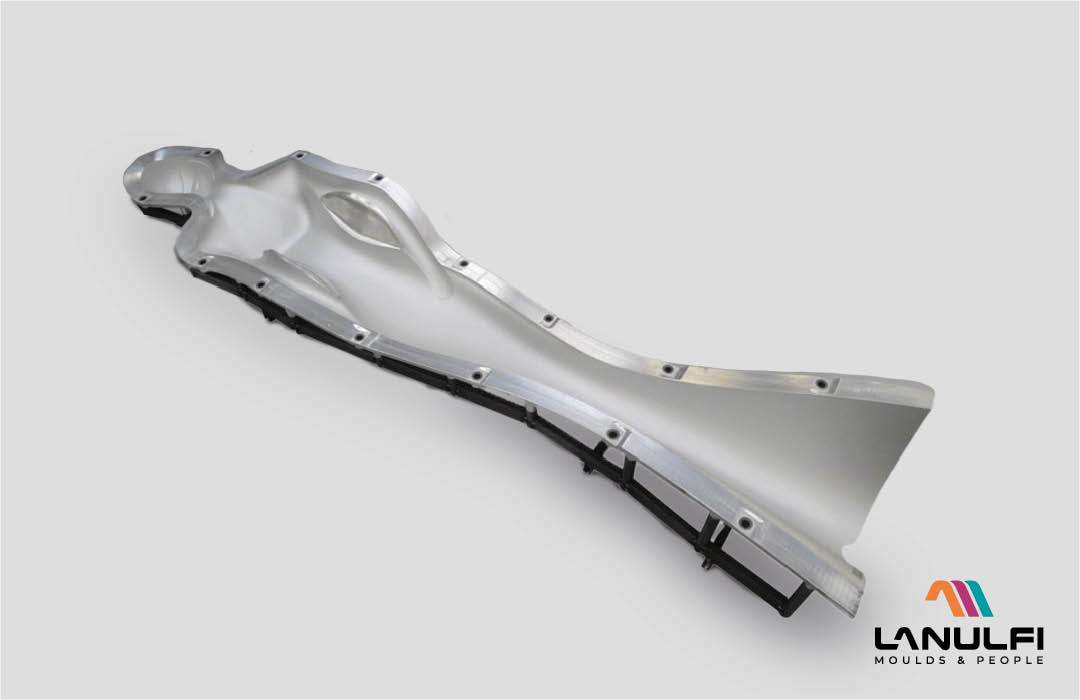

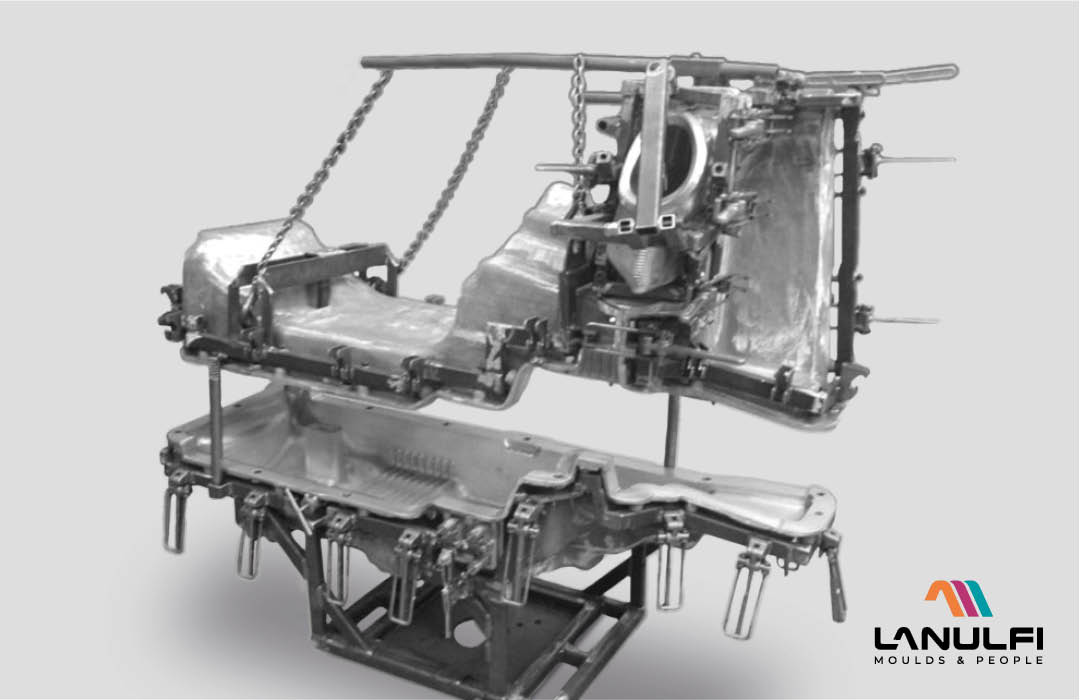

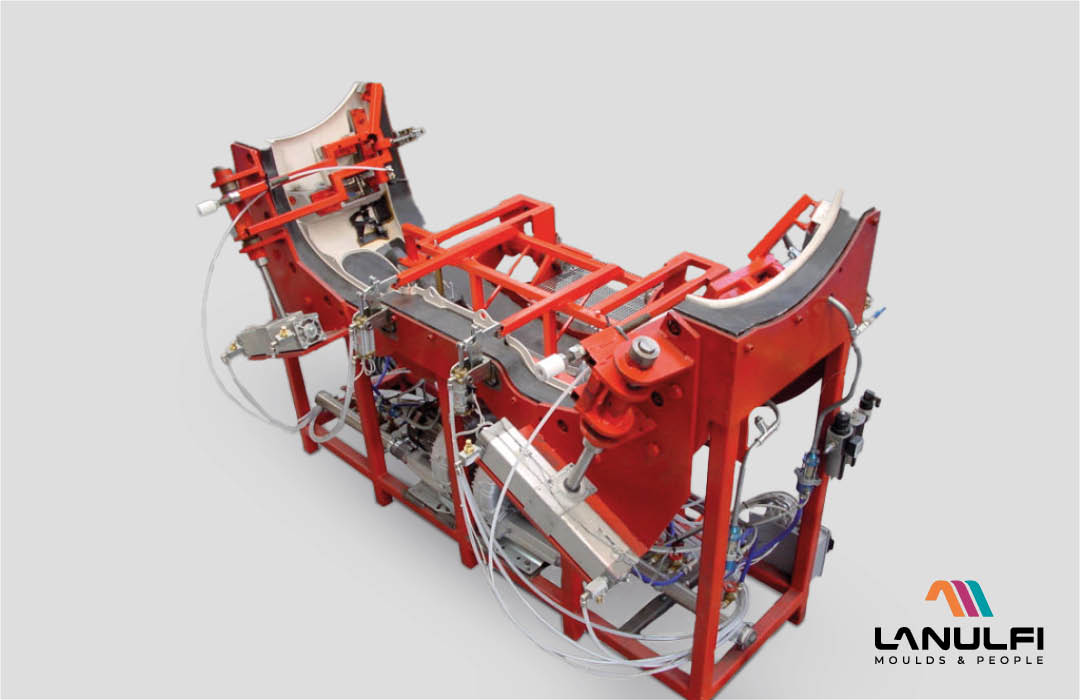

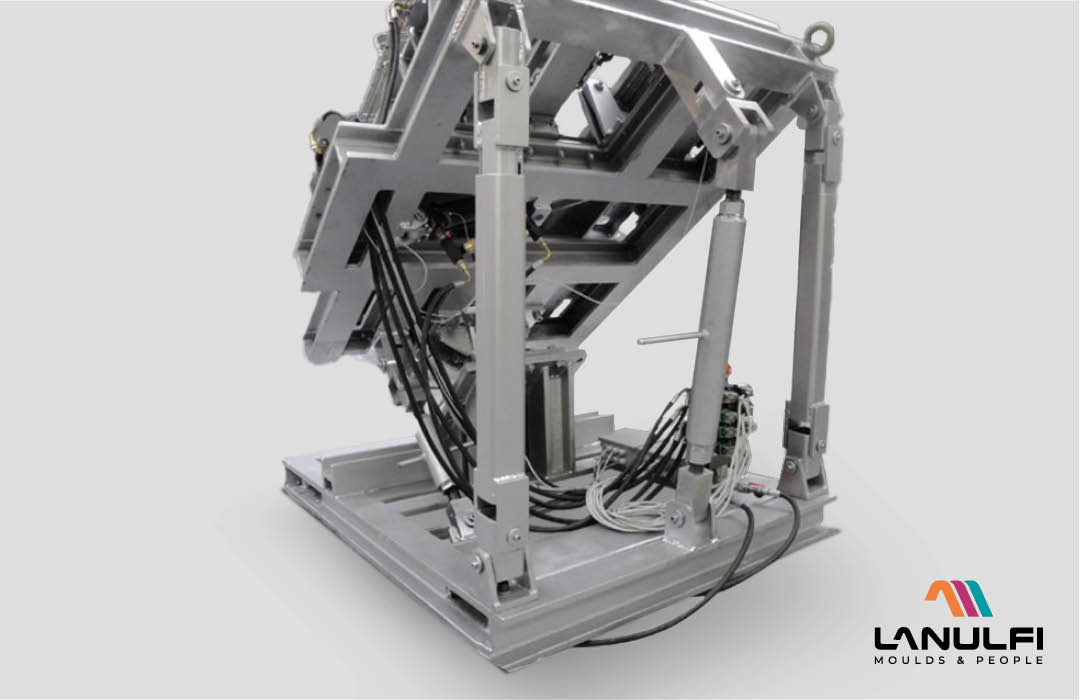

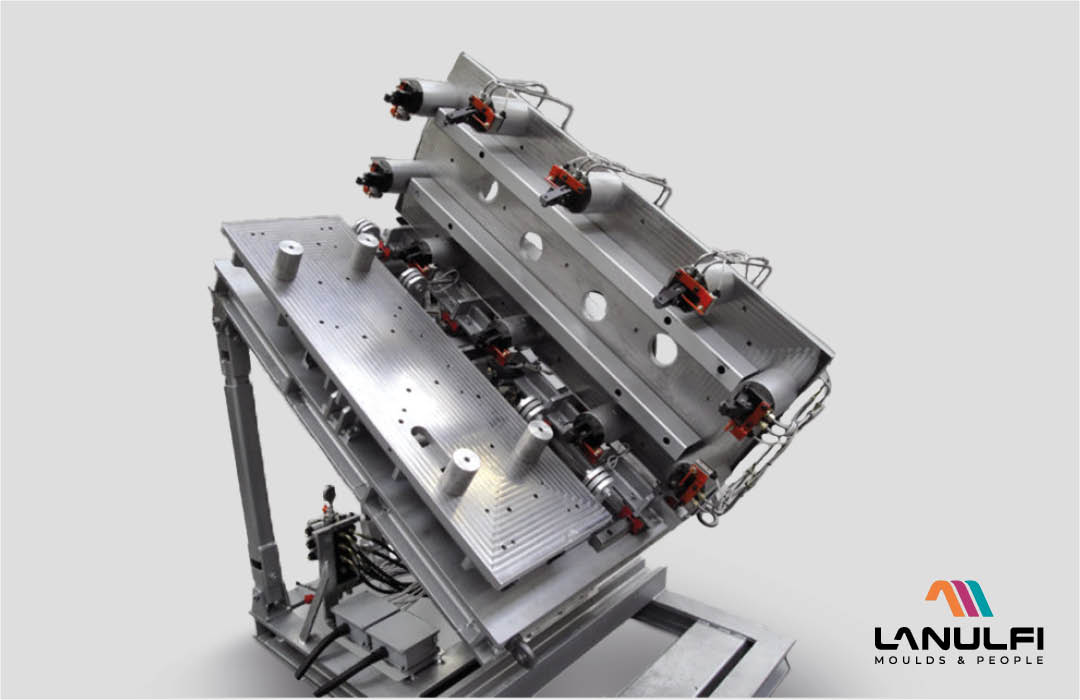

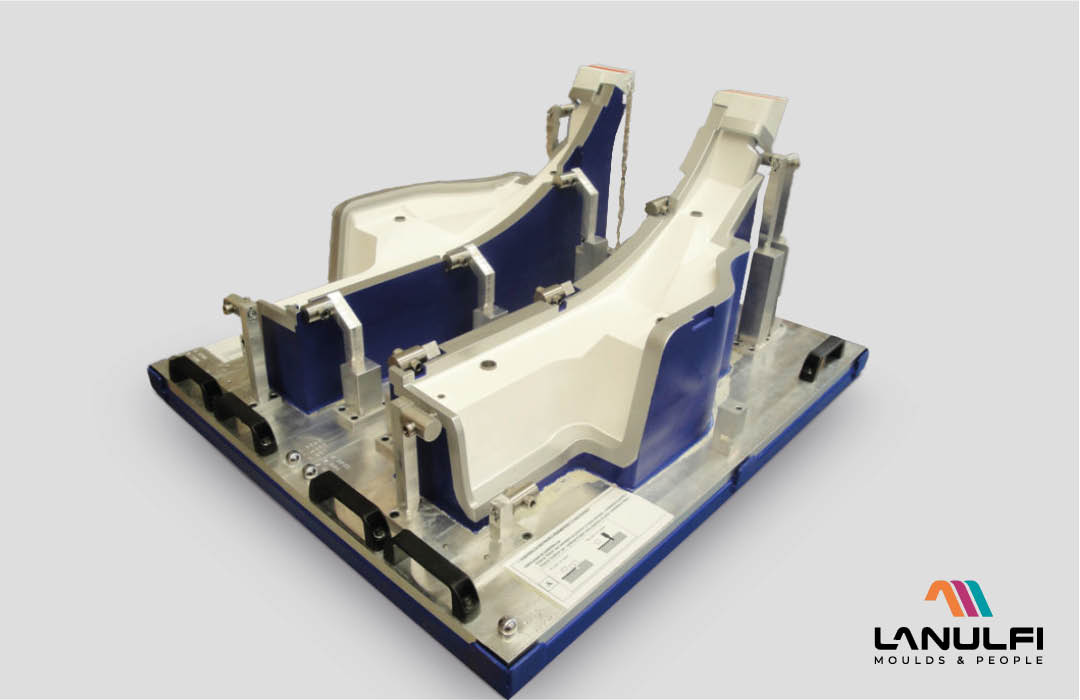

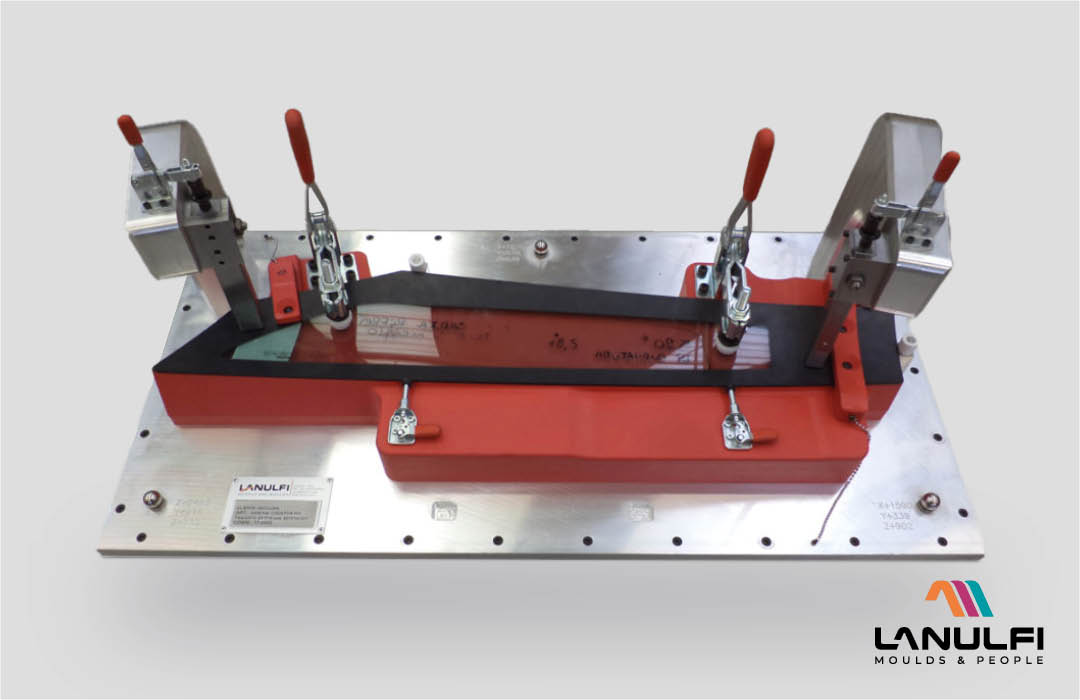

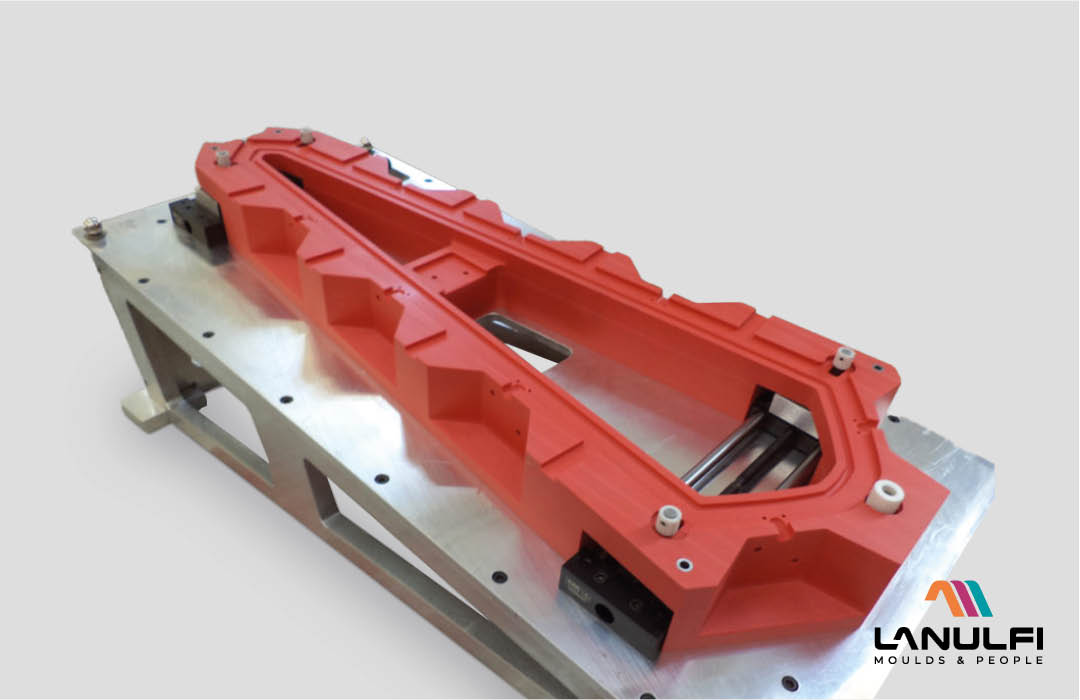

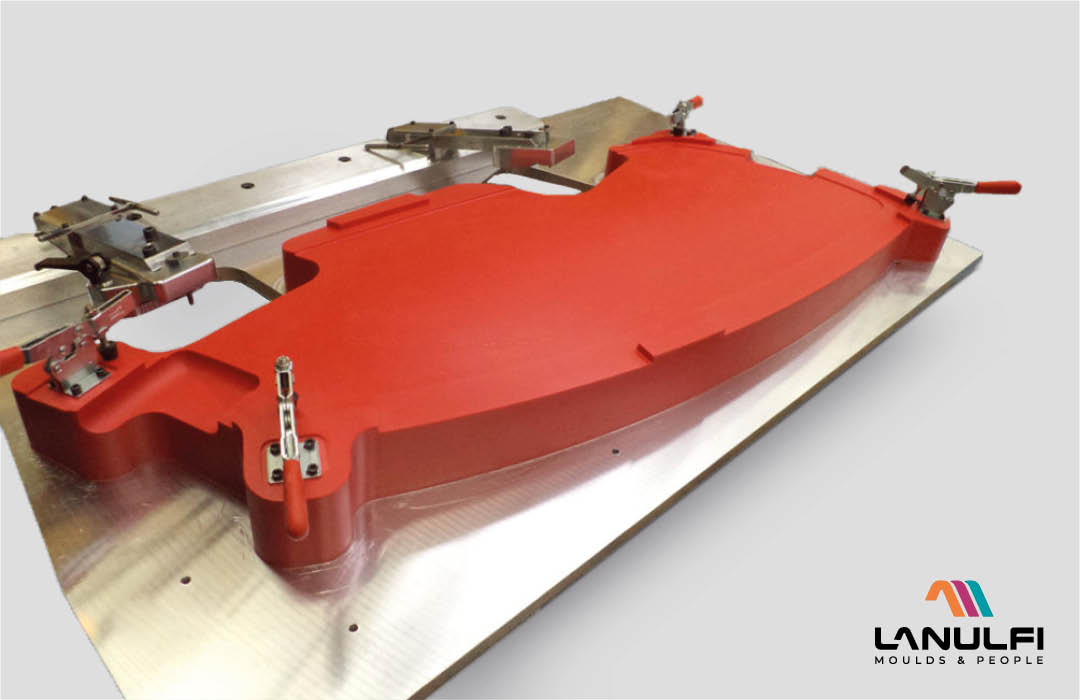

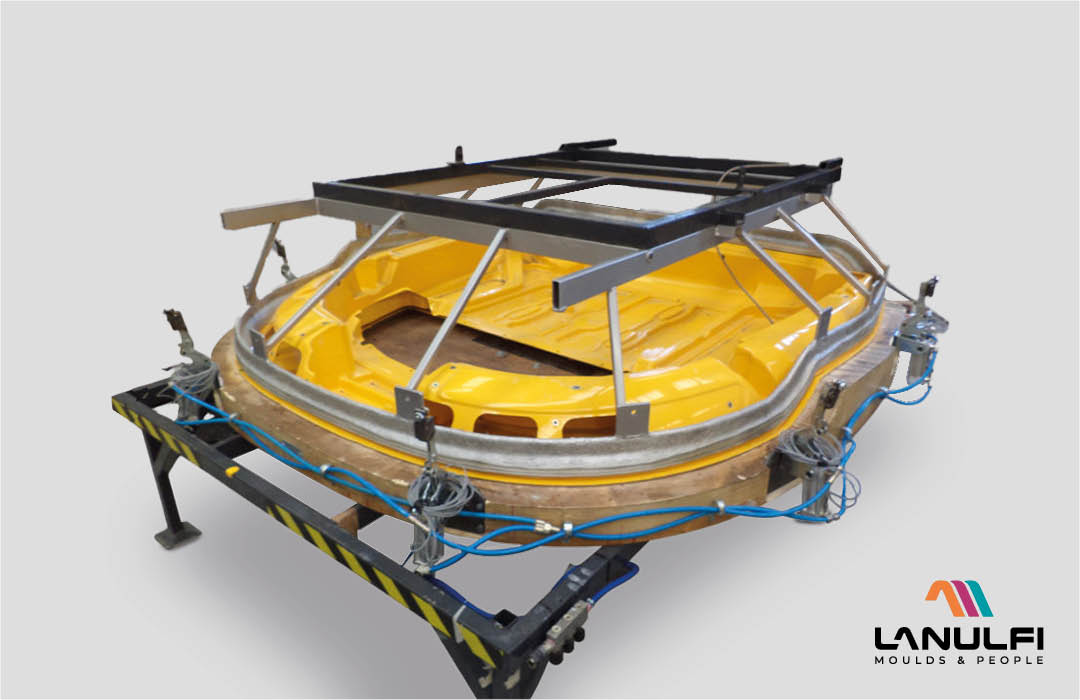

Special equipment

Design and construction of special equipment, bonding jigs, inspection jigs and gauges, etc.

Those who choose Lanulfi know that our company is able to provide technological and professional support that goes far beyond the supply of the mould itself and also includes all the additional equipment necessary for the production and control of the parts such as:

- measuring and laying jigs

- cutting templates with cutter or water jet

- cold or thermostat bonding templates

- transport jigs

- "stand-alone" presses

Examples of completed projects

WE ARE ALWAYS READY

TO HELP YOU

Would you like more information or a new project? Contact us by filling in the following form.